Nanofiltration (NF) of water is a process by which water is passed through a semi-permeable membrane with nano-sized pores for filtration and purification. This type of filtration system retains particles between 1 and 10 nm in size – in other words, between 1/1,000,000 and 1/100,000 of a millimetre – smaller than those filtered by microfiltration and ultrafiltration, but larger than those removed by reverse osmosis. Thin polymer films form the membranes predominantly used in conventional NF, which otherwise require water to be passed through them under high pressure.

However, a recent innovation by a team of engineers and scientists led by Professor Chuyang Tang, Department of Civil Engineering, University of Hong Kong, Institute of Environment and Ecology, Shenzhen International Graduate School, Tsinghua University, and Centre for Membrane and Water Science and Technology, Ocean College, Zhejiang University of Technology, Hangzhou, all in China, is set to transform the NF system as we know it.

“Vacuum-driven NF could be a promising and low-cost alternative by utilizing simple components and operating under an ultra-low vacuum pressure (<1 bar),” say the professors and engineers in their paper Ultra-permeable silk-based polymeric membranes for vacuum nanofiltration, published in the scientific journal Nature Communications.

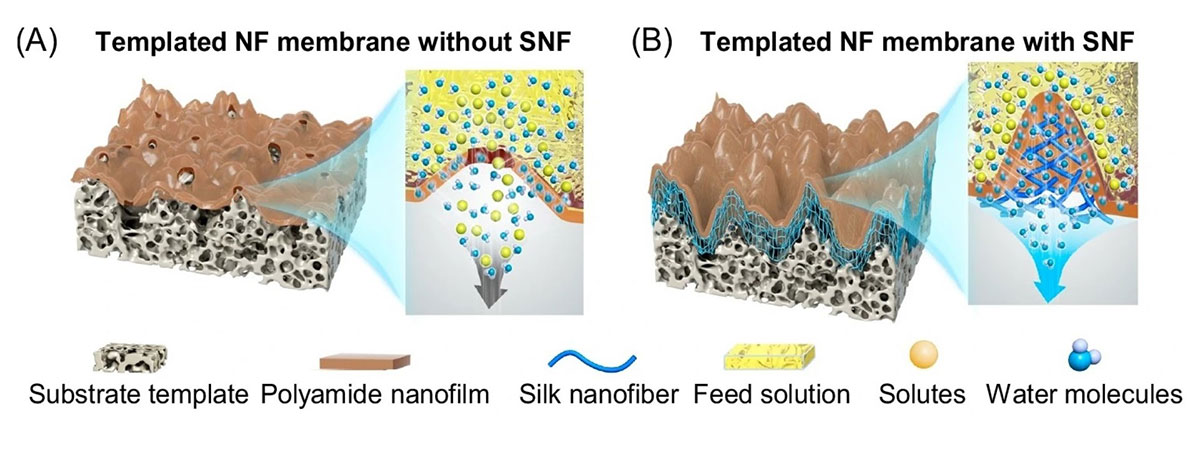

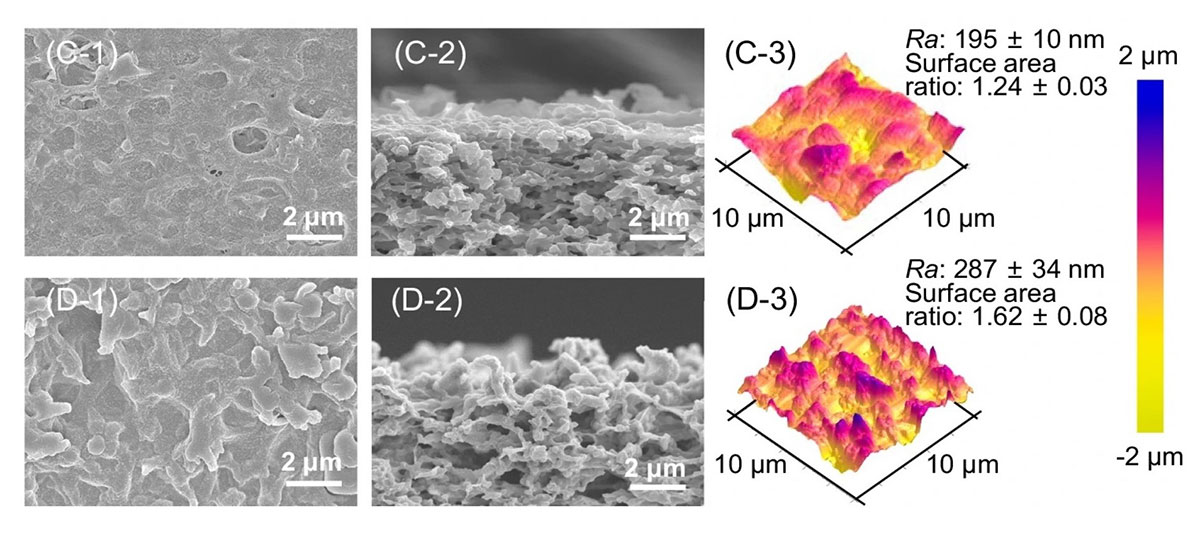

Indeed, current methods require extremely high pressures – up to 10 bar – to operate, which leads to the need for bulky equipment, high energy consumption and, consequently, high operating costs. In other words, according to the scientists, commercially available membranes are incapable of achieving a relevant water flux under vacuum conditions and without resorting to such high pressures. Therefore, “we fabricated a silk-based membrane with a crumpled and defect-free rejection layer,” say the researchers, capable of providing a water flux of 56.8 litres per m2 per hour at the indicated vacuum pressure of 0.9 bar, and filtering out more than 99 per cent of organic contaminants, including perfluorinated compounds – or “eternal chemicals”, which we discussed in another article below.

The analysis reveals that “silk-based ultra-permeable membranes”, the professors write in Nature Communications, “may offer close to 80% reduction in specific energy consumption (…) compared to a commercial benchmark”. This is a promising discovery, as it uses a natural and biodegradable material. At the same time, the filtering system becomes an energy-efficient process and therefore more environmentally friendly and sustainable than current systems. If that is not enough, it is a filtration system with an easy “practical application in real industrial settings”. So be it.

If you want to know more about other innovations in water treatment processes – and more about perfluorinated substances – here is the promised article:

» Innovation: water purification with ultrasound

Sources: Nature Communications, Ecoinventos, Wikipedia.

Images: Nature Communications, Pexels