On 8th December (2024), the South China Morning Post (SCMP) published a story that was quickly echoed by many other newspapers and publications around the world. The headline read: “China’s “explosive” ironmaking breakthrough achieves 3,600-fold productivity boost”. The article refers to “more than a decade of intensive research” by Professor Zhang Wenhai of the Chinese Academy of Engineering and his team of engineers leading up to its publication in the Chinese journal Nonferrous Metals. Specifically, the SCMP refers to a new method for producing iron that is “not only faster and cheaper, but also better for the environment”.

It is a method that uses a technology known as “flash ironmaking” instead of the more conventional blast furnaces. As described by SCMP, the process involves injecting finely ground iron ore powder into an extremely hot furnace. It is precisely the fineness of the ore particles that allows an “explosive chemical reaction” to be triggered inside the blast furnace, SCMP quotes the project engineers as saying.

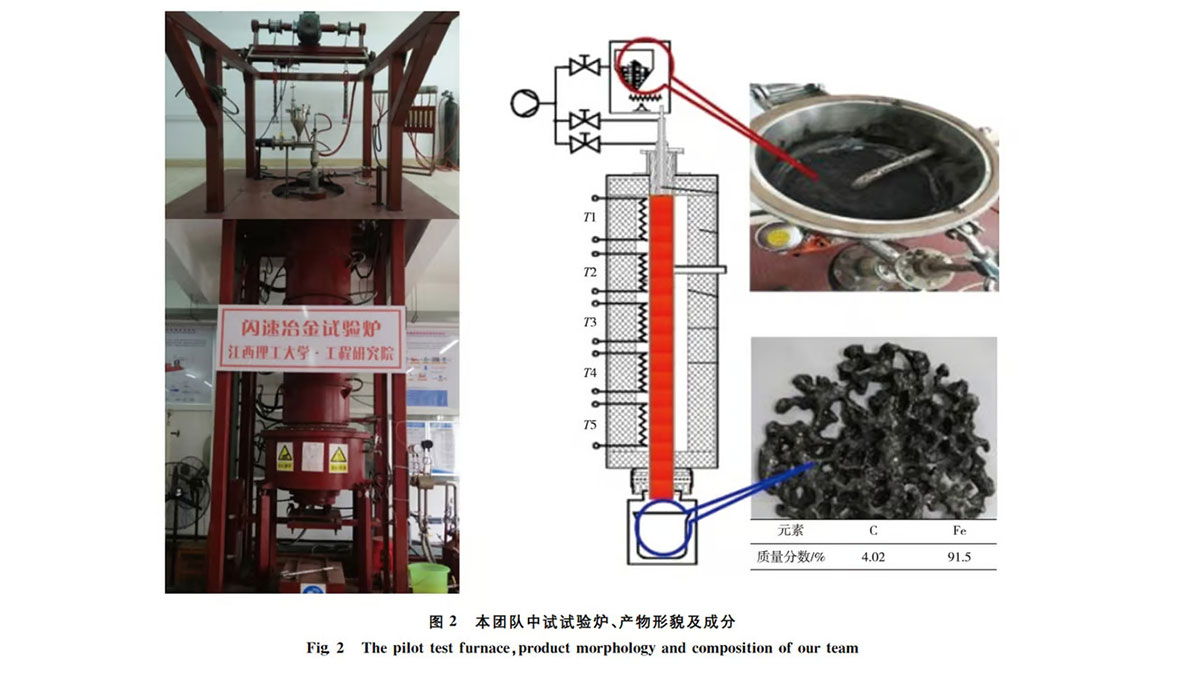

This reaction results in “bright red, glowing liquid iron droplets that rain down”, on the bottom of the furnace, and a stream of high-purity iron that can go directly to smelting or “one-step steelmaking” – again, a direct quote from the Chinese engineers provided by SCMP – so that the process is completed “in just 3 to 6 seconds, as opposed to 5 to 6 hours for traditional blast furnaces”. Now we understand the headline, when he claims that the new method means a 3,600-fold or more increase in the speed of iron production. As if that were not enough, the new process completely eliminates the need for coal, which would help China’s iron and steel industry achieve near-zero carbon dioxide emissions.

One of the technical difficulties engineers have faced is the “ore-spraying lance”. To trigger the explosive chemical reaction discussed above, the iron ore must be dispersed in a high-temperature tower space with a large specific surface area so that it retains a high reducibility. So, according to SCMP, Zhang’s team developed a “vortex lance” capable of injecting, with uniform distribution, 450 tonnes of iron ore particles per hour.

The “vortex lance” is likely to be one of the main innovations brought by Zhang’s team’s research, as the American Iron and Steel Institute in the United States, together with the University of Utah, Berry Metal Company, ArcelorMittal USA, The Timken Company and the United States Steel Corporation have already conducted research on the same method between 2012 and 2018. However, it does not seem that they were able to produce the breakthroughs that the Chinese engineers are now announcing.

In any case, the instant production method was already known for non-ferrous metals. However, Academician Zhang’s team has completed an instantaneous casting technology capable of directly producing liquid iron. In fact, they obtained a patent in 2013 and have been refining the method ever since. “Completed pilot and laboratory tests have demonstrated the feasibility of the process”, Zhang told SCMP.

You can read the full research paper, published in Nonferrous Metals – although you will need to know Mandarin – here:

» Research Progress of Flash Ironmaking Technology.

Sources: South China Morning Post, Hackaday, Interesting Engineering, US Department of Energy.

Images: Zhang Wenhai.