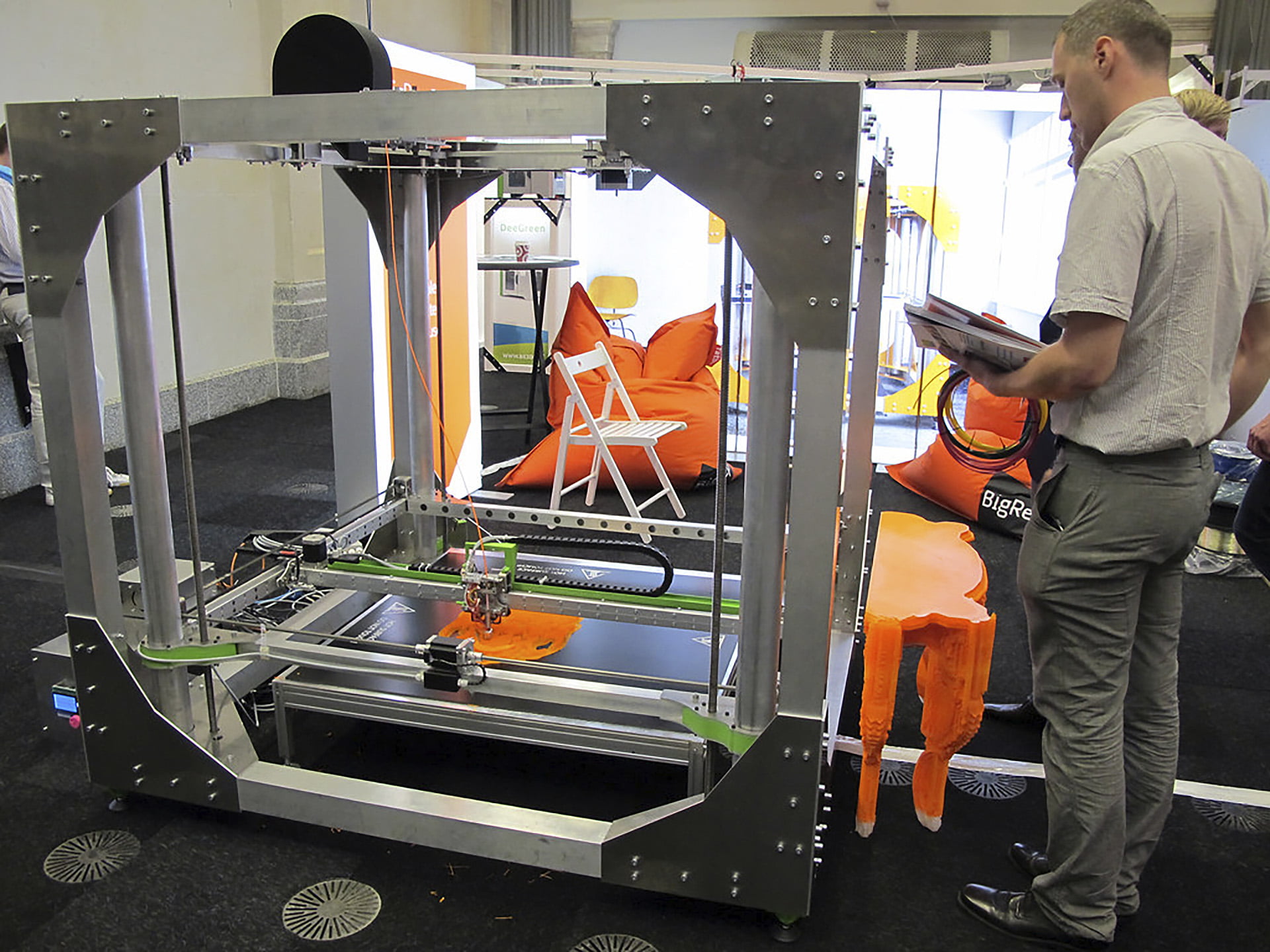

We are currently witnessing a race for dominance in large format industrial 3D printing, and especially in polymer deposition printing or FRP (Fibre Reinforced Polymer), which produces large pieces.

There are already numerous commercial printers in the 1 to 2 m³ range, which print with conventional materials such as ABS (Acrylonitrile Butadiene Styrene) or the more robust Polycarbonate.

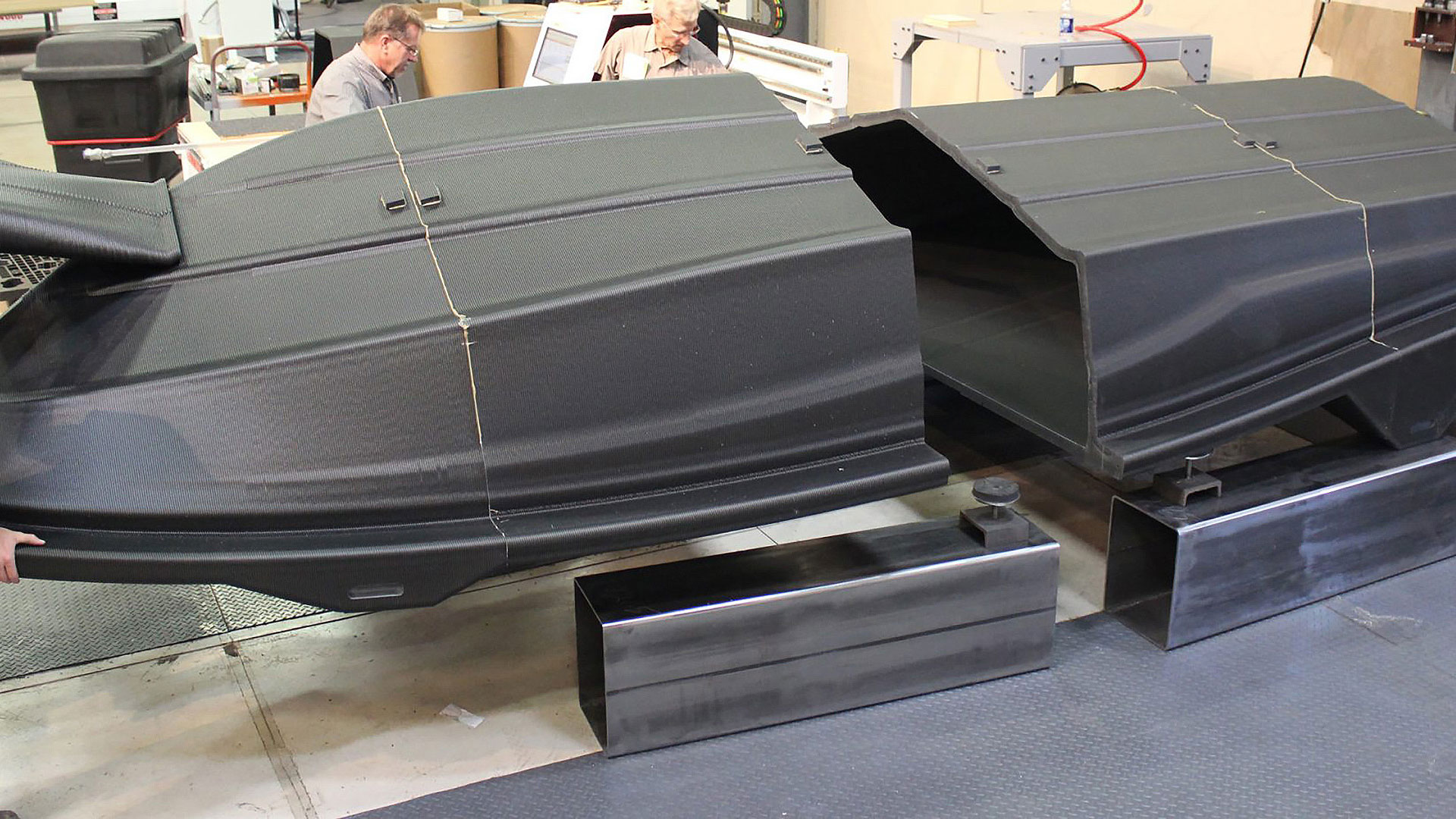

In even larger formats and with reinforced materials, we know of experiences such as that of the University of Maine, in the USA, which printed the 3Dirigo boat. Weighing 2.2 tonnes and measuring 7.62 m in length, it is the largest 3D printed object in the world. It was printed using a mixture of plastic and cellulose. The printer used had a capacity of 227 kilos per hour, and was 30 x 6.70 x 3 m.

In Europe, the RISE institute (Swedish Research Institute) and the company Pioner collaborated to commercially produce the Pioner 14 Active. This is a boat printed layer by layer, using robotic arms from ABB Ltd., from a mixture of plastic and fibreglass. The same material is used in Moi Composites’ MAMBO model, a boat with an eye-catching shape that could not be obtained from moulds.

Even more surprising is the first one-piece, 15-metre-long printed bridge developed in Shanghai by Polymaker and Shanghai Construction Group. Just as amazing as the retractable bridge in the same city.

Amusement Logic pays the utmost attention to these advances, always with the aim of innovation and research in the leisure and tourism sector, and for their application in the design and construction of the projects of the water and theme park, hotels and resorts, campsites, shopping centres, etc., that are entrusted to it.

By Miquel Solís, senior architect in Amusement Logic’s Architecture Dept.