The use of concrete as a construction element takes us back to the Roman Empire – many of their buildings still stand today – however this material began to be used in the way with which we are familiar today, from the 19th century onwards.

From its first use, humans have investigated the way of perfecting its characteristics through testing, additives, different application methods and combining it with other materials. This evolution, however, has not been able to stop the deterioration of concrete structures that are subjected to environmental agents, earth movements and all kinds of wear; with high repair costs.

However, recently a group of researchers in which the universities of Binghamton and Rutgers participated, has been able to develop a solution to this problem: self-repairing concrete.

The investigation focused on finding the way to solve the small cracks that occur in structures, which are an access path for pollutants. Starting with the knowledge of biological systems’ capacity to self-repair, the search for this new concrete needed to find an element, which, mixed in during the manufacture process, would later react on coming into contact with water.

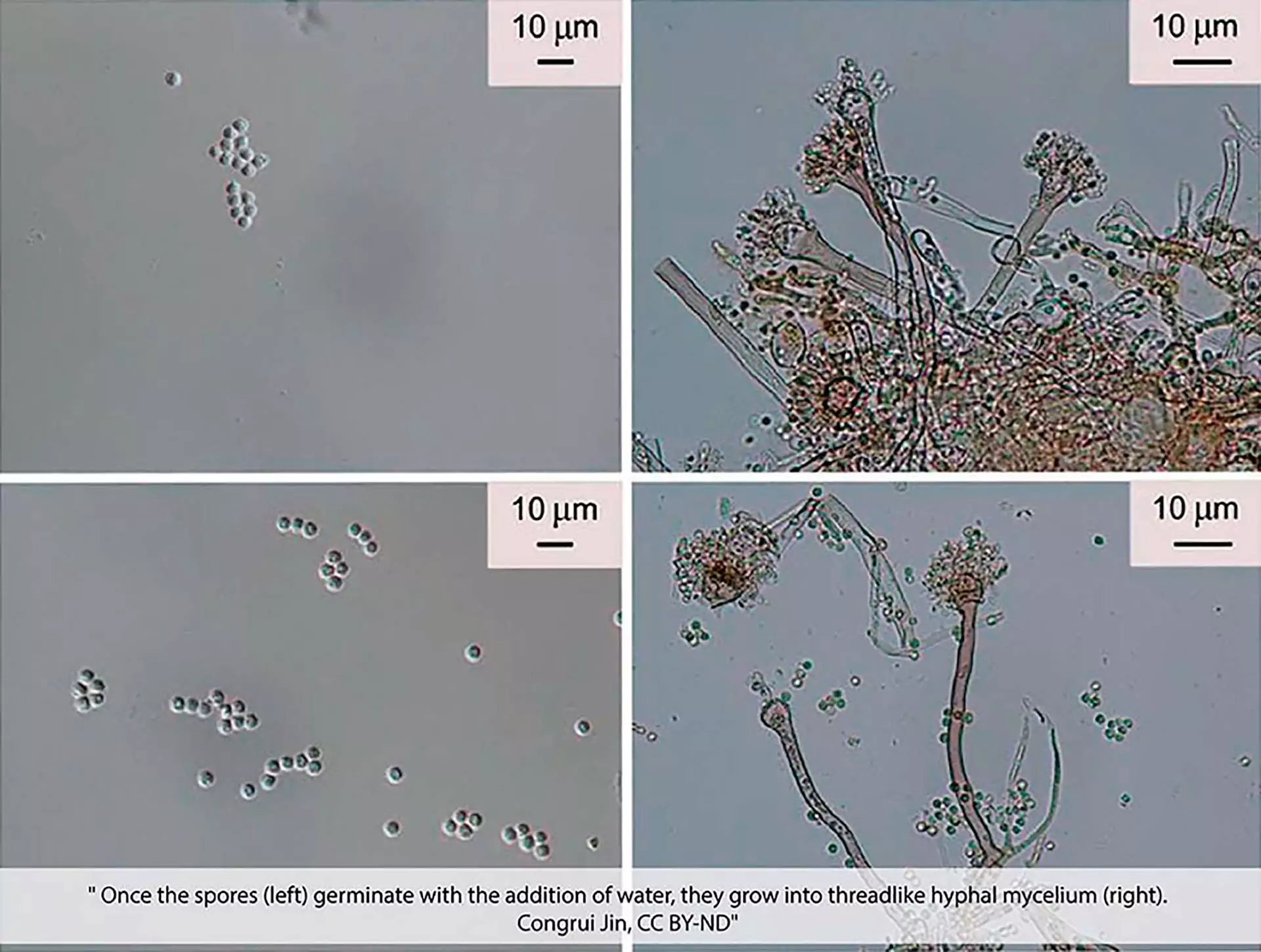

The element in question is a fungus called Trichoderma reesei. As water filters through the cracks in the concrete, the spores germinate and as they grow, they act as a filler, impeding the entrance of more water or other contaminants.

Moreover, this fungus is environmentally friendly. It’s non-toxic for human health and it is already used in other industrial processes. Although research is still under way, it’s very good news for the industry.