After several decades since Thomas Bock envisioned a future in which construction would be carried out by robots, robotics is beginning to make its presence felt in the sector through fully functional prototypes. In some cases, these are only robots partially made from conventional machinery such as cranes and excavators, but in others they are machines created to solve specific processes. This is the example of the SAM 100 robot, produced by the US firm Construction Robotics.

ccording to calculations, the average number of bricks a bricklayer can lay in a working day is approximately 500. SAM 100, on the other hand, exceeds that figure with a rate of 3,000 bricks per day. The use of this robot, which can lay bricks faster than a skilled labourer, means a significant cost reduction in the construction of new homes.

The prototype has a robotic arm, a pump for pumping cement and a tank where the bricks are stored. However, SAM 100 still requires human assistance to feed the brick storage tank.

Other large construction companies have started to develop new prototypes, with developments such as the following, amongst others:

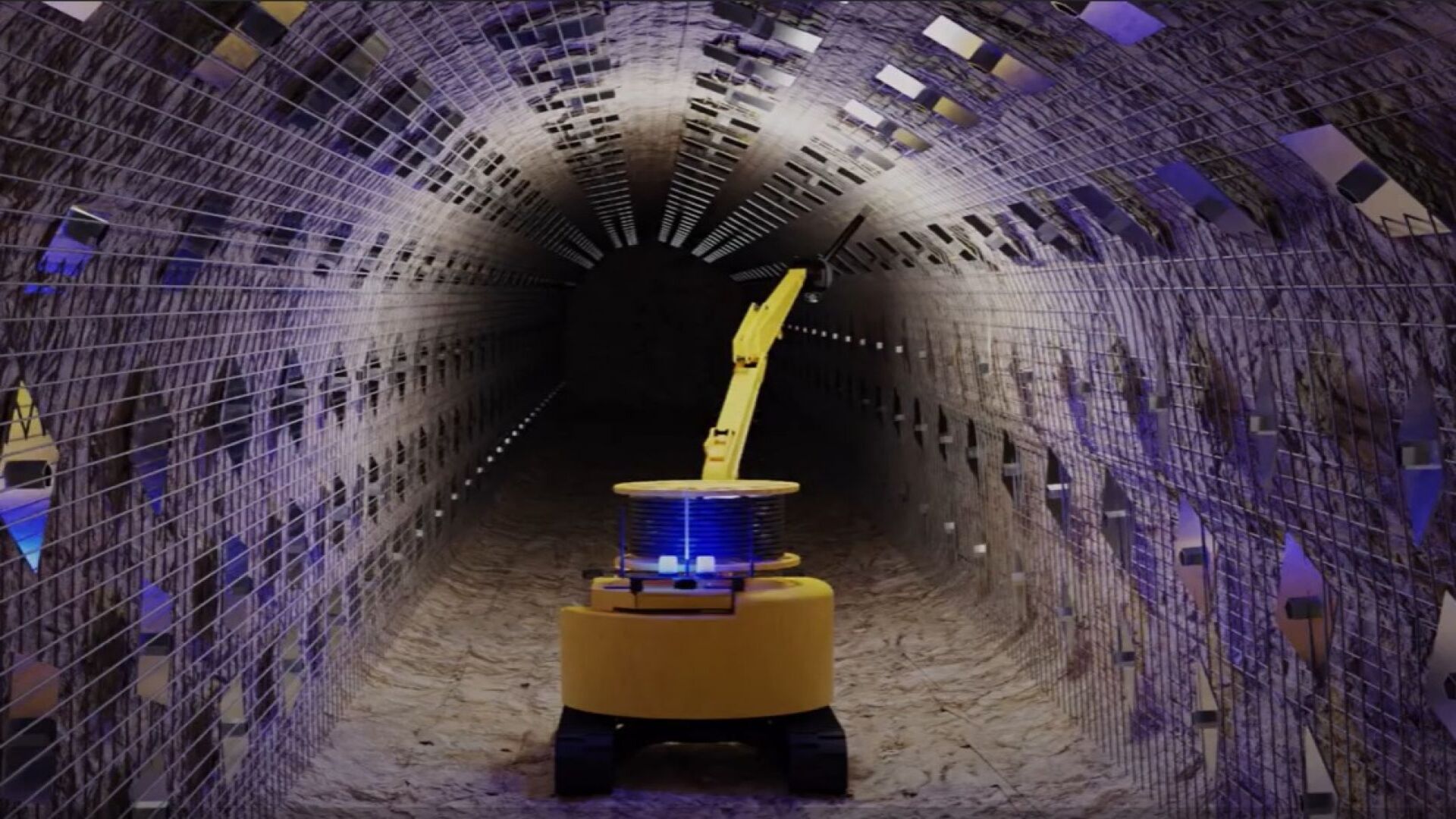

- The European BADGER project, led by the Carlos III University, is developing a microtunneling robot to build trenchless infrastructure.

- The ROBIM project, proposed by a Spanish consortium, is developing an autonomous robotic system for the technical inspection of buildings with the aim of refurbishing them.

By Jean Carlos Soto, Senior Structural Engineer in Amusement Logic’s Architecture Dept.