Welding is a process of fusing parts together using extreme heat and/or pressure. It means that after cooling, the parts are transformed into a fixed joint. Many of the different welding techniques were developed during the industrial revolution and have evolved extensively in recent years. These techniques are now applied more easily and with better results.

Depending on the purpose of joining parts, different welding methods are used:

- Homogeneous welding, also known as autogenous welding: this occurs when the filler materials for it have the same composition. Within this category there are two types: soft soldering, as for example in cables and electrical components; or brazing, which requires significant resistance to withstand very high stresses, as in the case of structural welding.

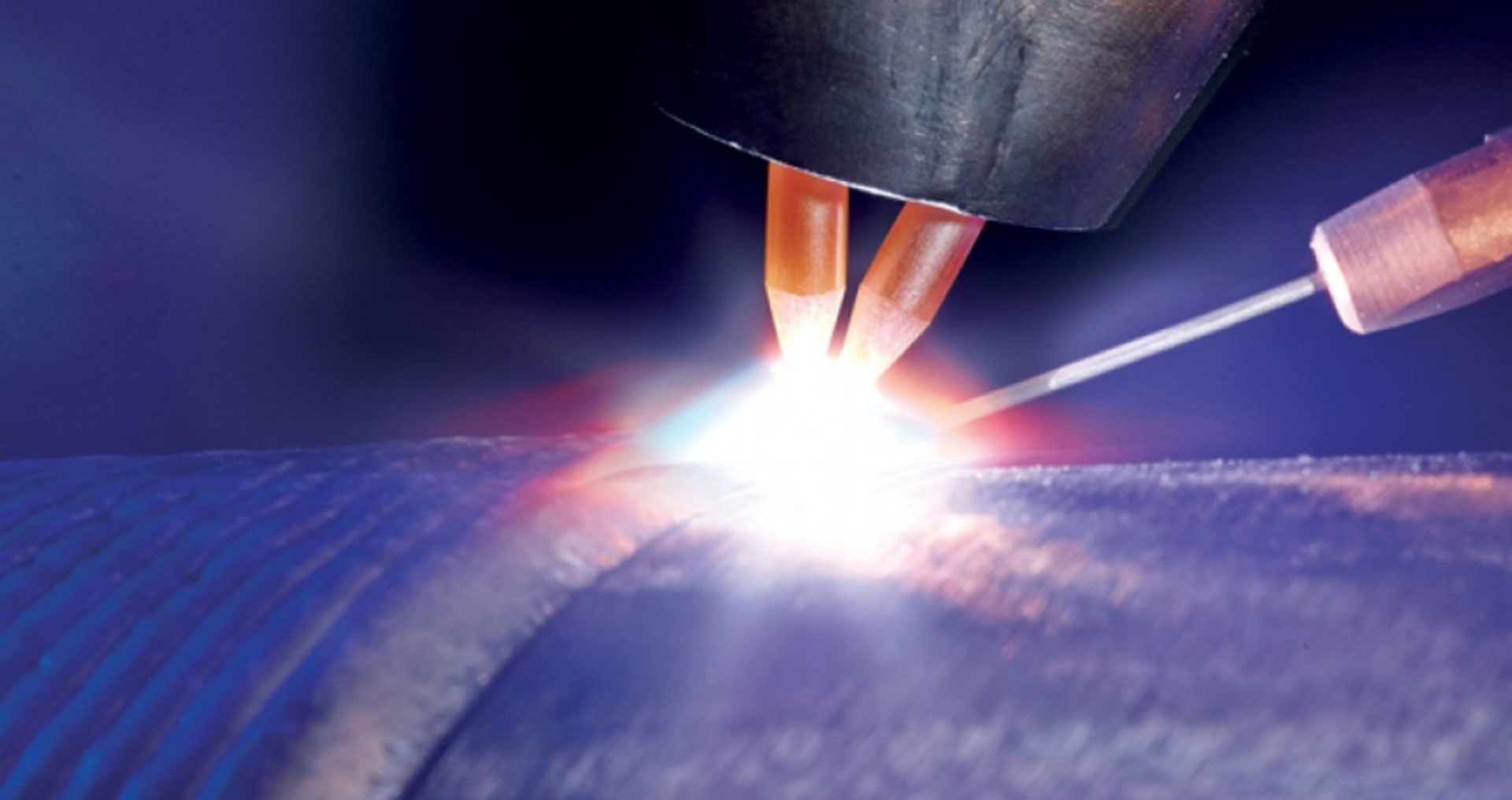

- –Heterogeneous welding: this consists of welding materials of the same or different composition, with a different filler metal. Within this modality, it can occur by pressure, when the materials are joined in a plastic state by means of heat; by fusion, that is, when the materials are melted at high temperatures and then fused (either through the use of laser, electricity or when it is oxyacetylene); or by gas, when it is produced by the combustion of acetylene in oxygen at temperatures above 3200 ºC (in MIG-MAG mode, which stands for Metal Inert Gas and Metal Active Gas, or TIG, which stands for Tungsten Inert Gas).

By Jean Carlos Soto, Senior Structural Engineer in Amusement Logic’s Architecture Dept.

Share This Story, Choose Your Platform!