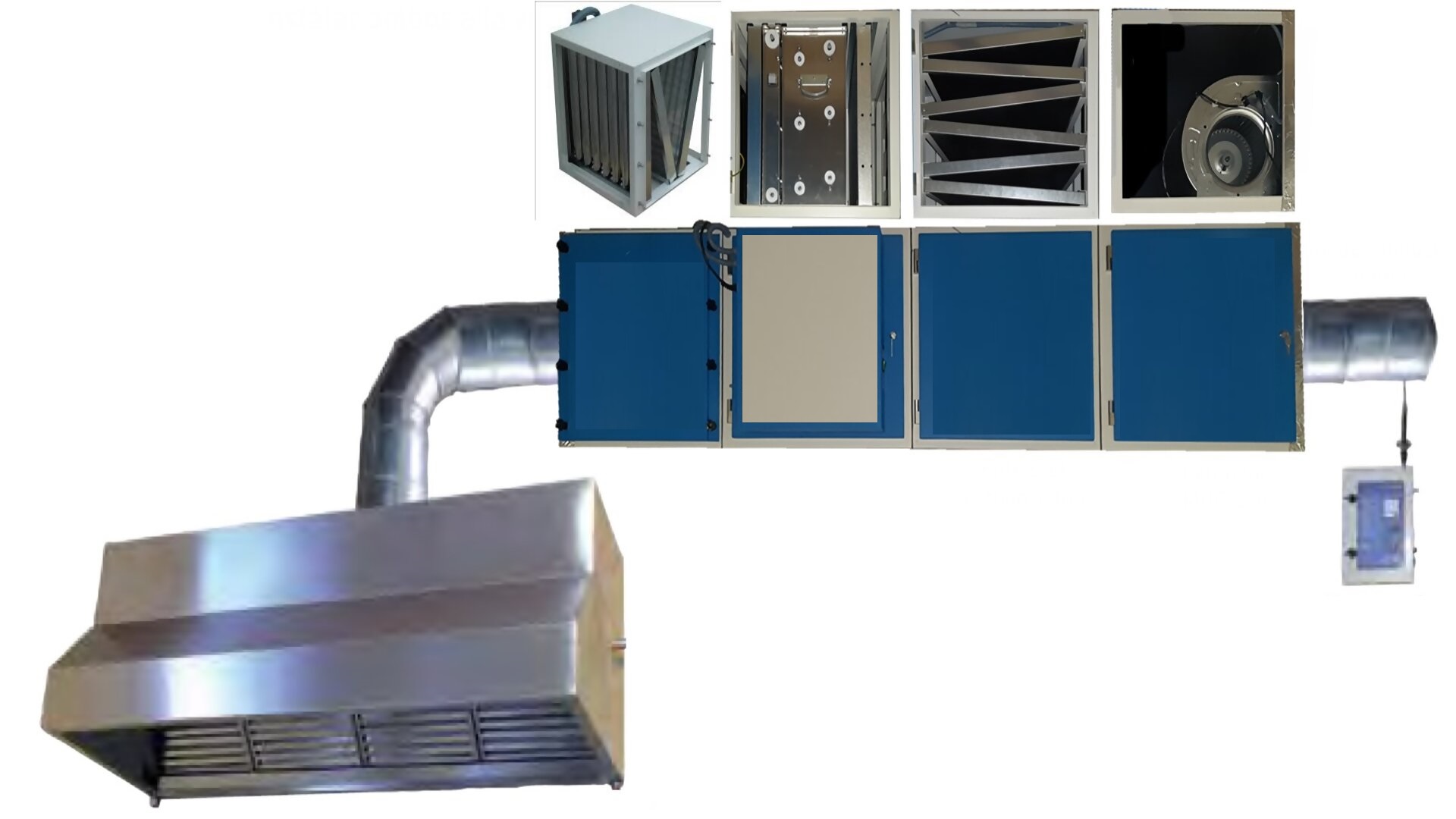

In the design and construction of industrial kitchens for the new catering projects that Amusement Logic tackles, one of the first problems to overcome is the ideal location of the fume extraction hood and its corresponding exhaust duct to the outside. In some cases, this location conditions the layout of the kitchen and the upper floors, through which the duct must run until it reaches the building’s roof. However, nowadays there is a technology that avoids these conditioning factors and opens up greater possibilities for the design and construction of this type of installation.

So, to the traditional set of louvred and activated carbon filters, we can add two new filtering stages: bipolar ionisation and ozonation. With these, we achieve an efficiency of over 98% in the filtering of fumes. After the process, the fumes are transformed into particle- and odour-free air. In this way, the new treatment circumvents the smoke emission requirements of most current legislation. The fumes filtered in this way are assimilated to other types of foul air produced in catering facilities, and can be extracted from the building’s façade and not only from the roof. These two new filtering stages open up new possibilities for the design of this type of installation, and lead to a significant reduction in construction costs. Finally, they make it more viable for projects where there is no possibility of extending an extraction duct to the roof of the building.

By Darío Mazzolari Tortajada, senior MEP engineer in the Architectural Department of Amusement Logic