Construction is constantly advancing thanks to its permeability to new trends and new technologies. One of these trends is precisely the concern for sustainability, which is transferred to its processes and the materials it uses, among other issues. Prefabrication, for example, has made a strong entry into construction as a process that not only saves costs, but also saves waste and greenhouse gas emissions. With regard to materials, there is also a field of opportunities opening up in construction.

The use of recycled materials, such as plastics, is one of the new developments in construction. In particular, one of the uses of recycled plastics is in the production of prefabricated bricks. Currently, the construction market shows two clear trends in this respect:

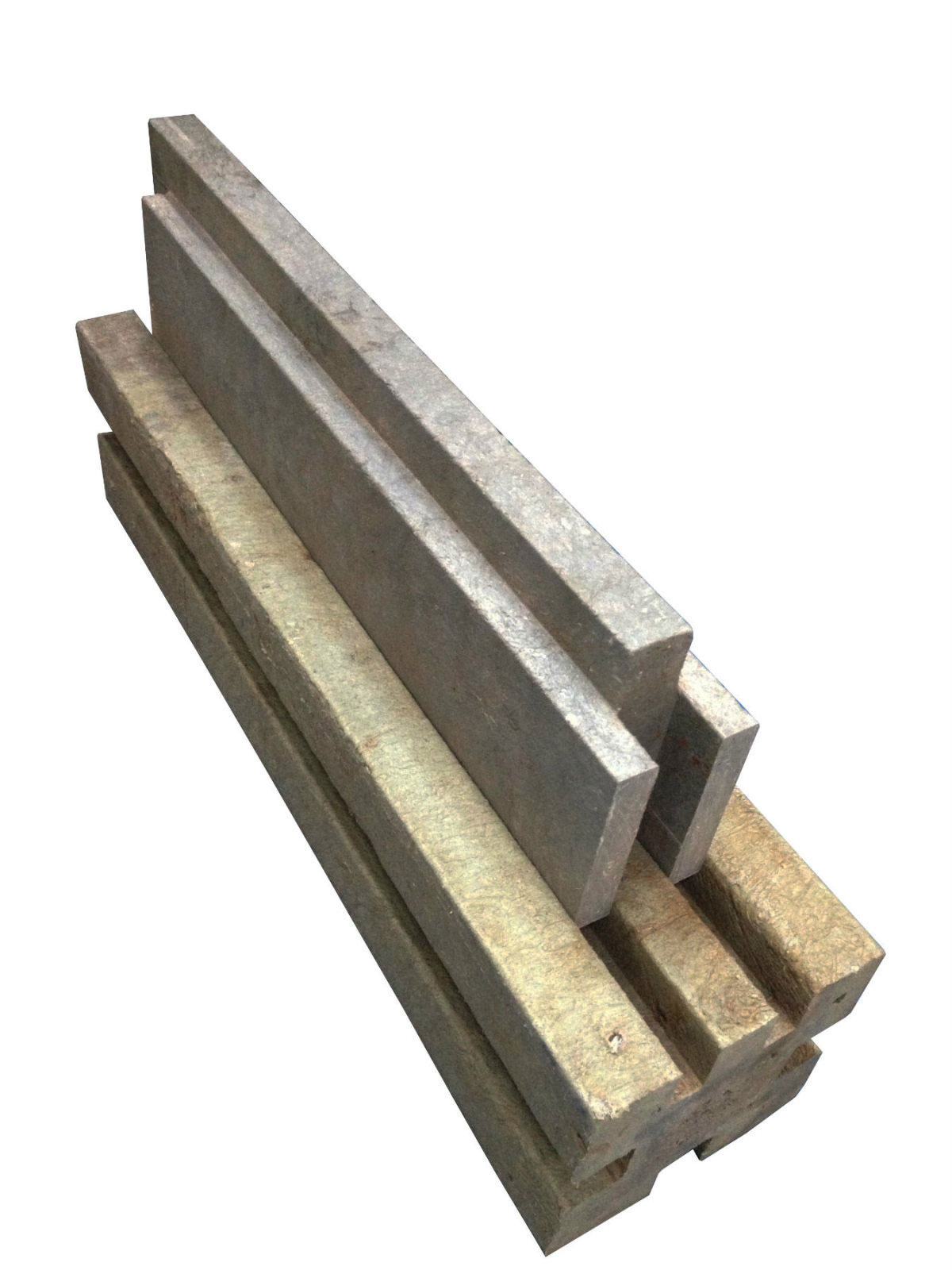

-One related to the composition of the bricks: in this respect, regardless of the shape of the brick, mixtures of plastics or cellulose with cement or clays are used for their manufacture.

-Another concerns the geometry and shape of the bricks: new shapes are being experimented with to make them easier to lay, more efficient and quicker to build.

Finally, this new type of brick improves buildings’ thermal, acoustic and structural performance. If the prices of these new materials are reduced and delivery times shortened, the construction economy will undoubtedly open the door to these innovations. This is despite the fact that the goal of their future widespread use in construction is ambitious and that there are still barriers, perhaps more mental than otherwise, for end users. After all, this trend contributes to the renovation of traditional building systems, as well as to their sustainability.

By Jorge Laguna, head of the structures section of Amusement Logic’s architecture department.