Prefabricated structural steel has radically transformed the construction industry, as an innovative solution that streamlines project execution. The prefabrication of steel components is carried out in controlled environments, prior to assembly on site. This method has many advantages over traditional methods.

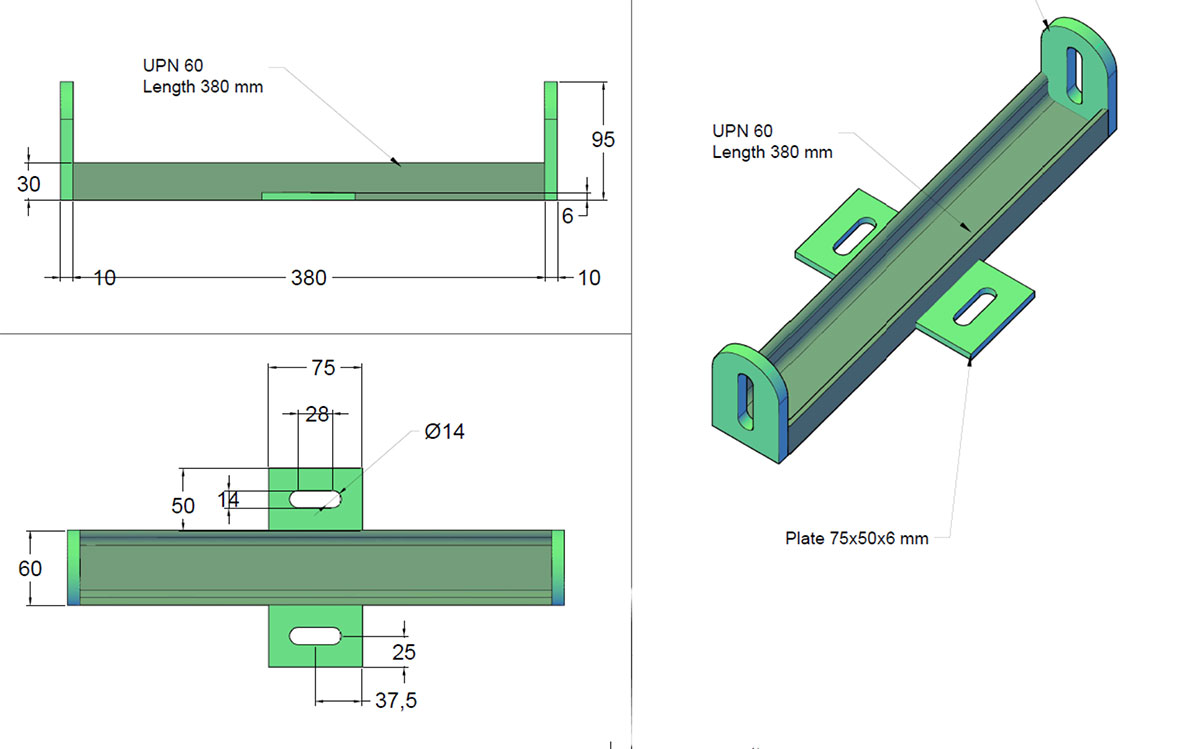

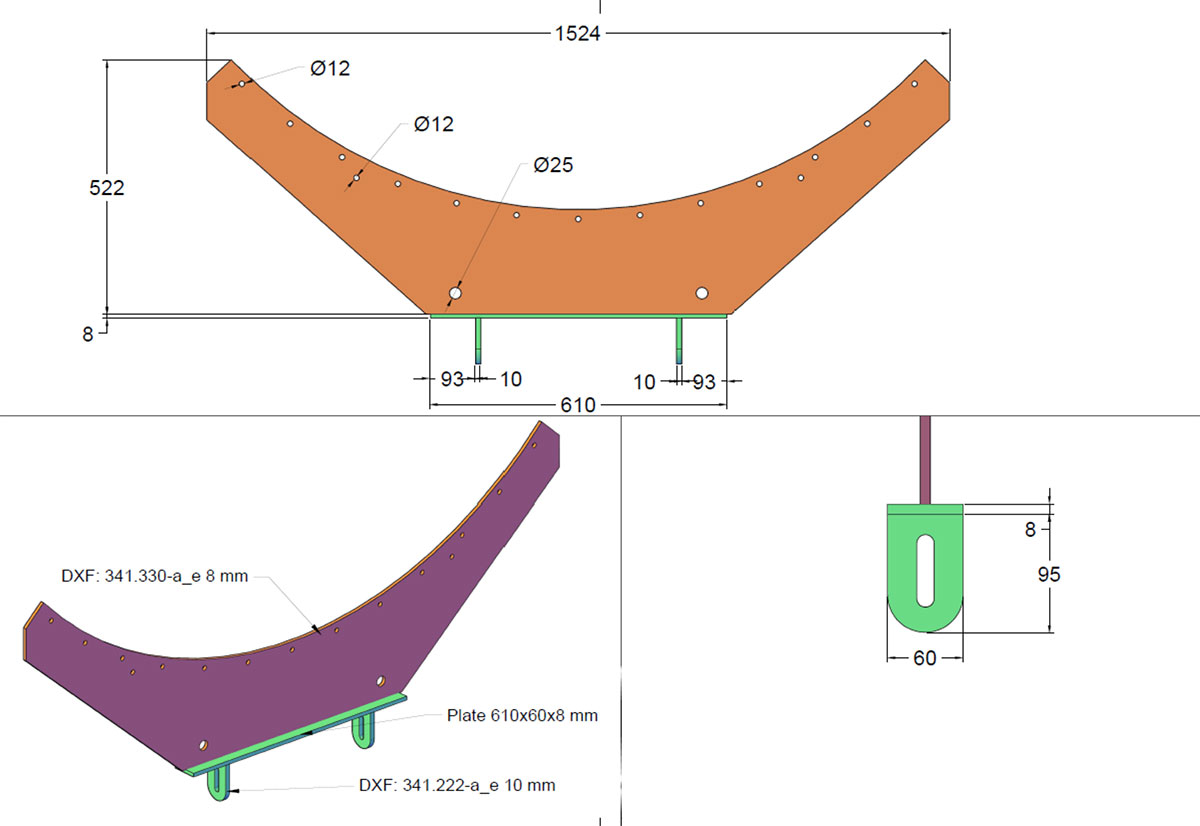

Whilst steel has historically been processed in an industrialised way, with simple parts manufactured in a workshop and assembled on site by bolting or welding, new technologies now allow the design of special parts in a parametric way. They take on a variety of complex two- and three-dimensional shapes.

For example, structures such as meshes covering large spans are made up of thousands of unique three-dimensional parts with complex geometries. Well, it would be almost impossible to assemble them all without the use of advanced computer systems. Thanks to these, construction errors are significantly reduced compared to those that usually occur with traditional methods. When carried out directly on site, factors such as weather conditions or variability in workmanship can cause unwanted deviations.

All in all, prefabricated structural steel represents a modern paradigm in the construction sector. Time reduction, dimensional accuracy, lower costs and a solid foundation for durable structures are some of its advantages. This method not only serves contemporary construction, but is projected into a future full of possibilities for efficiency and innovation.

By Alberto Lopez, Senior Structural Engineer at Amusement Logic’s Architectural Department