After decades of unsuccessful research, researchers at the Massachusetts Institute of Technology (MIT), in collaboration with Harvard University and laboratories in Italy and Switzerland, have finally been able to solve the mystery. The mystery lay in the factors that make Roman-period constructions so durable. Or, to put it another way, what made the mortar used for construction in Rome, its concrete, so efficient and resistant. The famous Pantheon of Agrippa in the Italian capital, which is at least 1,895 years old, or numerous aqueducts still standing in the territories of the ancient empire, are examples of the extraordinary quality and strength of the material.

Professor of civil and environmental engineering Admir Masic, with PhD candidate Linda Seymour and four others from MIT, announced their discovery to the world in an article published earlier this year in the journal Science Advances. Previously, as cited in architects’ studies at the time, volcanic ash from Pozzuoli in the Bay of Naples, present in the concrete used by the Romans at all ends of their domains, was thought to be a determinant of its durability and strength. However, after further and more thorough examinations, Professor Masic and his assistants came to new conclusions.

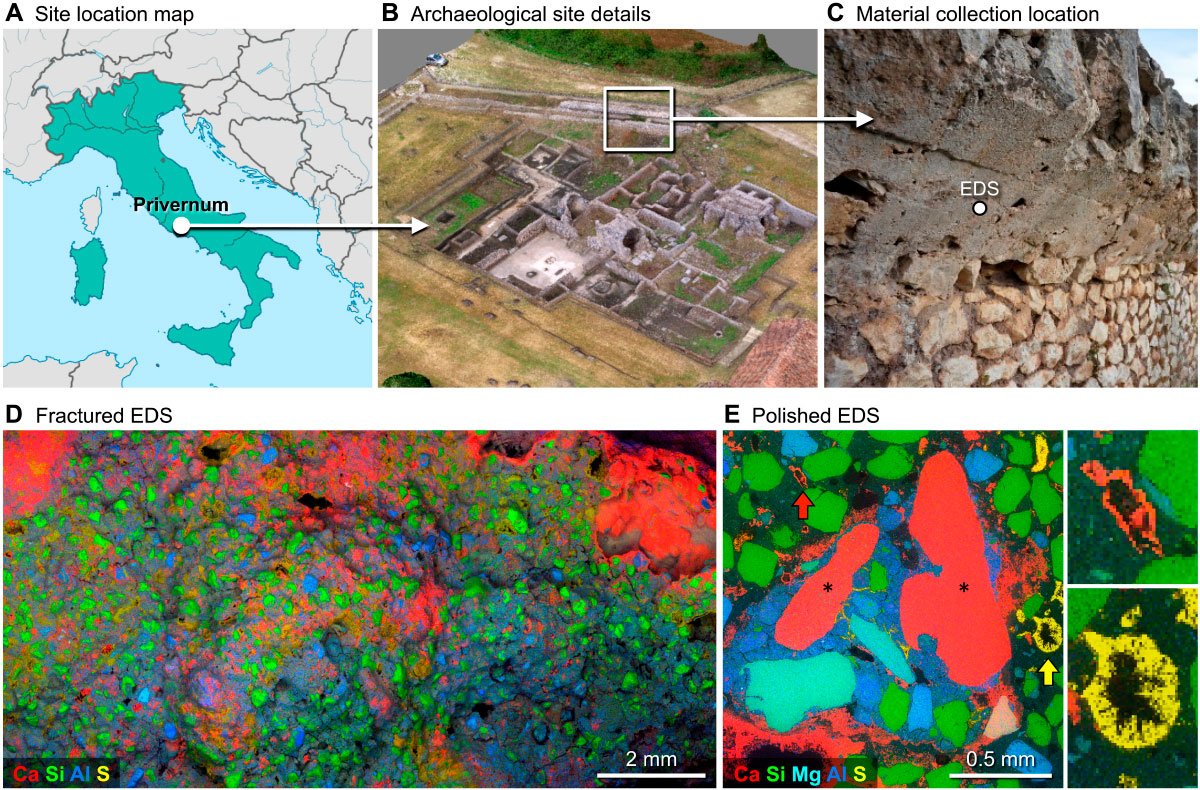

Indeed, ancient samples of Roman concrete contain, on a microscopic scale, small bright white mineral clusters or ‘lime clasts‘ (incidentally, present in every corner where Roman constructions exist). These calcareous clusters, Masic points out, “are not found in modern concrete formulations“. So, the question surfaced of its own accord: why was it found in Roman concrete? The answer came with the use of high-resolution imaging and ‘chemical mapping’ techniques developed for the first time in the lab for this MIT research.

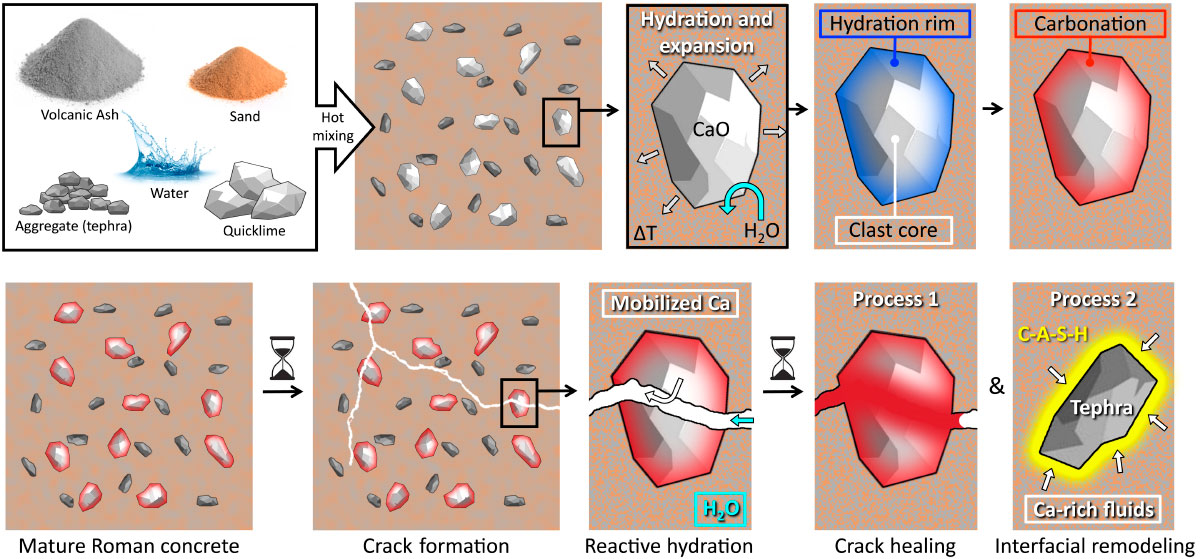

While it was historically assumed that lime was incorporated into Roman concrete by first combining it with water in a process known as slaking, spectroscopic examination pointed in another direction: the mixing of the material had taken place at extreme temperatures. The only way this could have been the case was due to the exothermic reaction produced by the use of quicklime “instead of, or in addition to, the slaked lime”. The first conclusion the research team came to was that hot mixing is one of the factors in the durability of Roman concrete.

According to Professor Masic, “when the overall concrete is heated to high temperatures, it allows chemistries that are not possible if you only used slaked lime”. Moreover, “this increased temperature significantly reduces curing and setting times since all the reactions are accelerated, allowing for much faster construction”.

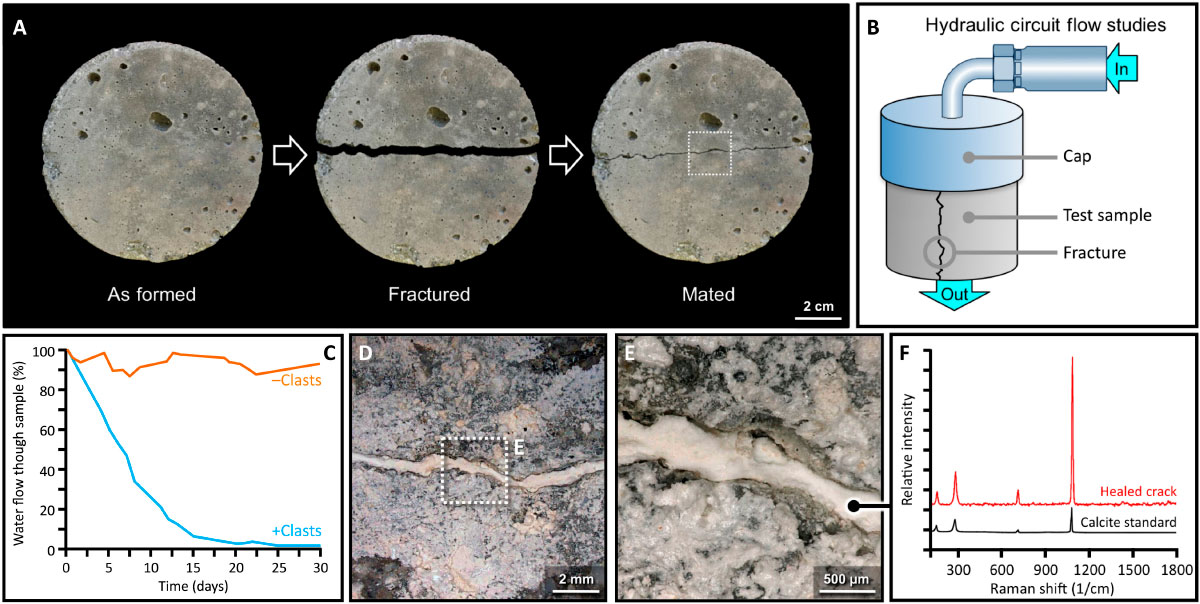

But in addition, after further tests, the scientists discovered another factor for the strength and durability of Roman concrete. The tiny lime clasts give the material a previously unknown self-healing capacity. Therefore, as soon as small cracks start to form in the concrete (which, by the way, are preferentially transferred through the lime clasts), the small lime clusters are exposed. When it rains, a saturated calcium solution is produced, which recrystallises as calcium carbonate and quickly fills these cracks, or reacts with the pozzolanic materials to further strengthen the composite material. Cracks are therefore automatically repaired before they deepen. In addition to the laboratory tests carried out by the research team, the examination of several samples of Roman concrete with cracks corroborated the hypothesis, as they were found to be filled with calcite.

To conclude, we leave you with the credits of the research team led by Professor Admir Masic and comprising Janille Maragh of MIT, Paolo Sabatini of DMAT (Italy), Michel Di Tommaso of the Instituto Meccanica dei Materiali (Switzerland), and James Weaver of the Wyss Institute for Biologically Inspired Engineering at Harvard University; the work was carried out with the help of the Archaeological Museum of Priverno (Italy).

Source: MIT News, Science Advances.

Images: Science Advances.