One of the many determining factors of a construction project is the type of soil where it will be located. This type of soil, which varies according to the area or region, is not always capable of supporting the loads of the building or facility in question, but is instead unstable and/or not very compact. In this case, it will be necessary to resort to geotechnical engineering techniques that improve and optimize the load-bearing capacity of the soil. One of the most effective techniques for this is pressure grouting or Jet Grouting.

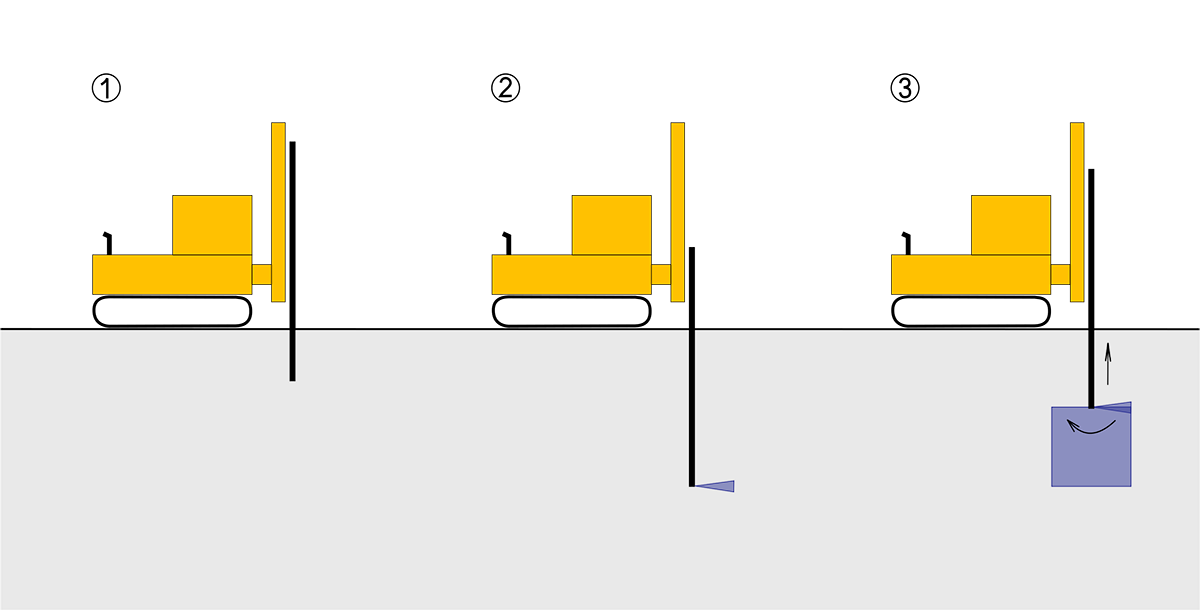

This method consists of injecting fluids at high pressure which, thanks to their kinetic energy, erode the structure of the soil. Subsequently, the eroded soil is mixed with a cementing agent, until it forms a homogeneous mass with better geomechanical properties than the original soil.

The process uses a mixture of water and, generally, cement as a cementing agent. However, other materials can also be used, such as bentonite, fly ash, quartz powder or chalk. The resulting soil has greater strength and lower compressibility and permeability.

Jet Grouting has its origins in the 1950s, when the first patent was registered in the United Kingdom. However, its development and refinement took place in Japan in the early 1970s. In the mid-1970s, the technique was introduced to Europe, where it has since experienced significant progress.

Jet Grouting is a highly versatile method, applicable to soils with different granulometries and levels of permeability, provided that its resistance to erosion does not exceed certain limits. For example, it is not recommended in rocky or highly weathered soils, where its effectiveness is limited.

By Jean Carlos Soto, Senior Structural Engineer in the Architecture Department of Amusement Logic

Header image: U.S. Army Corps of Engineers