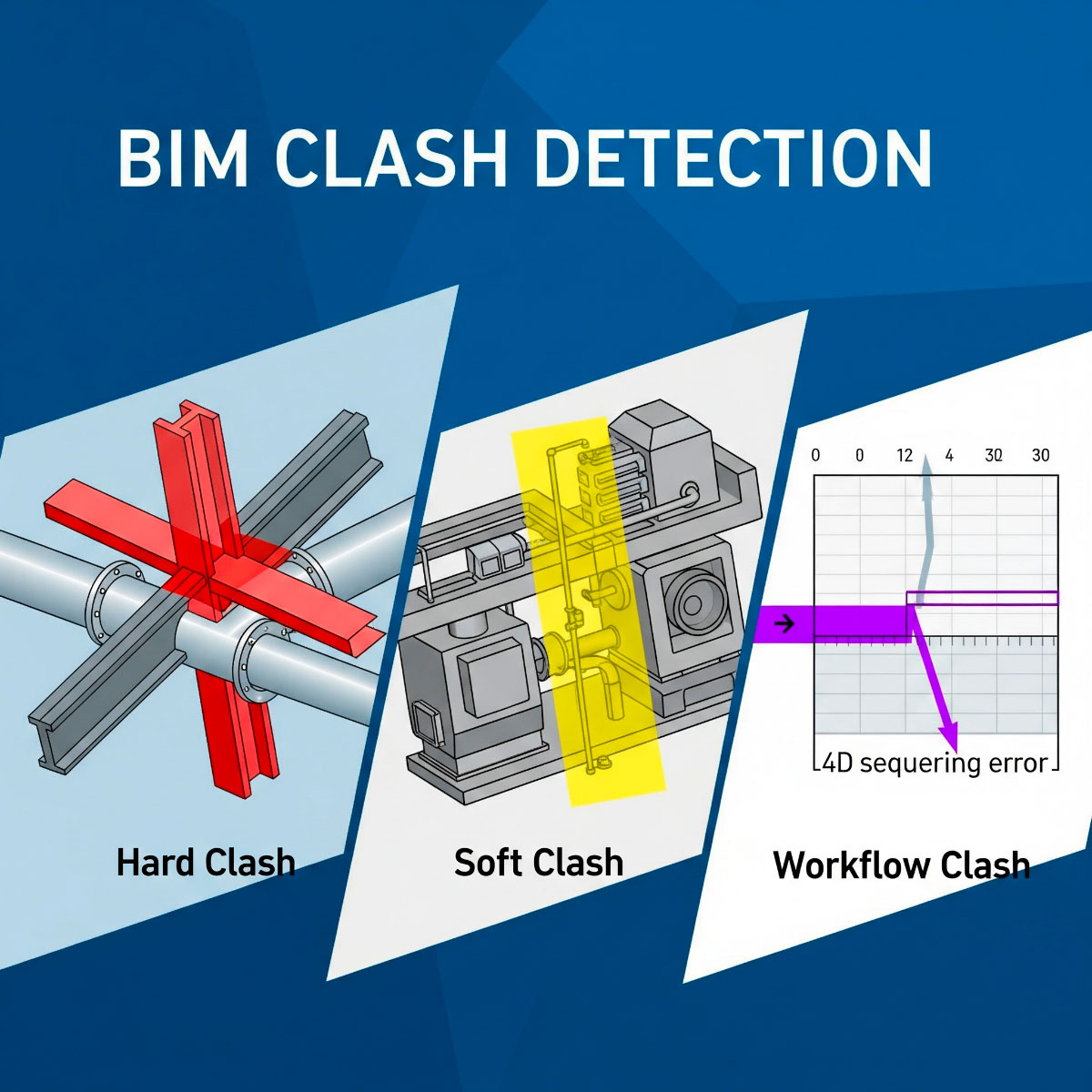

In construction, errors that go unnoticed at an early stage can lead to delays, repairs and even critical failures in execution. However, BIM (Building Information Modelling) methodology allows us to avoid such difficulties by early detection and identification of conflicts and interferences. This technique not only prevents two elements from occupying the same physical space, but also anticipates problems that could affect the construction, installations and even the future maintenance of the building.

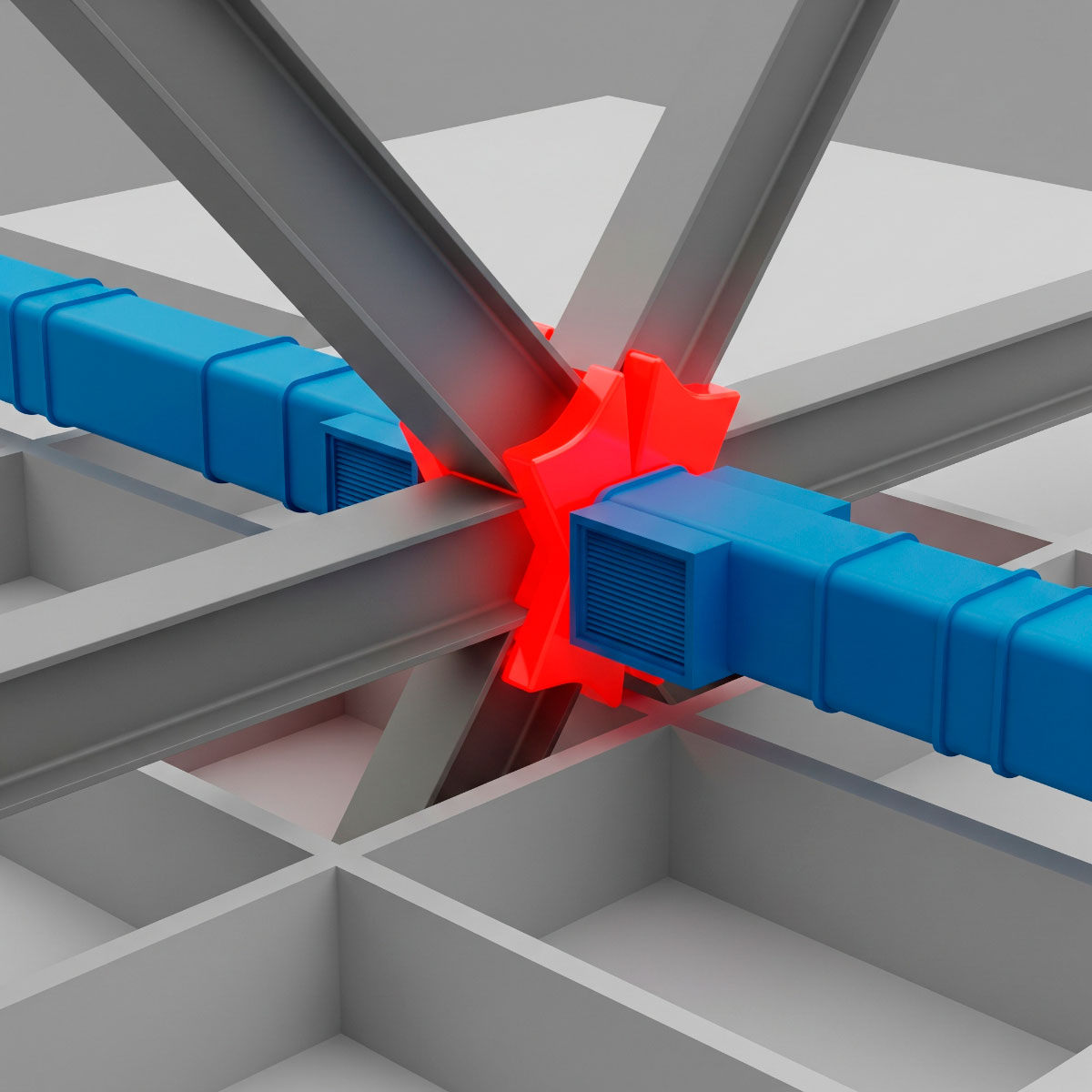

Physical interference: the most obvious conflicts

Physical interference occurs when two components of the model collide at the same point. A common example is a beam crossing a duct, an error that, if detected on site, would require redesigns, technical stoppages and rework. But identifying it in the design phase and correcting it with digital adjustments is possible in BIM, without impacting time or budget. A study by the US National Institute of Standards and Technology, among others, estimates that such conflicts accounted for up to 10% of the additional costs in traditional construction.

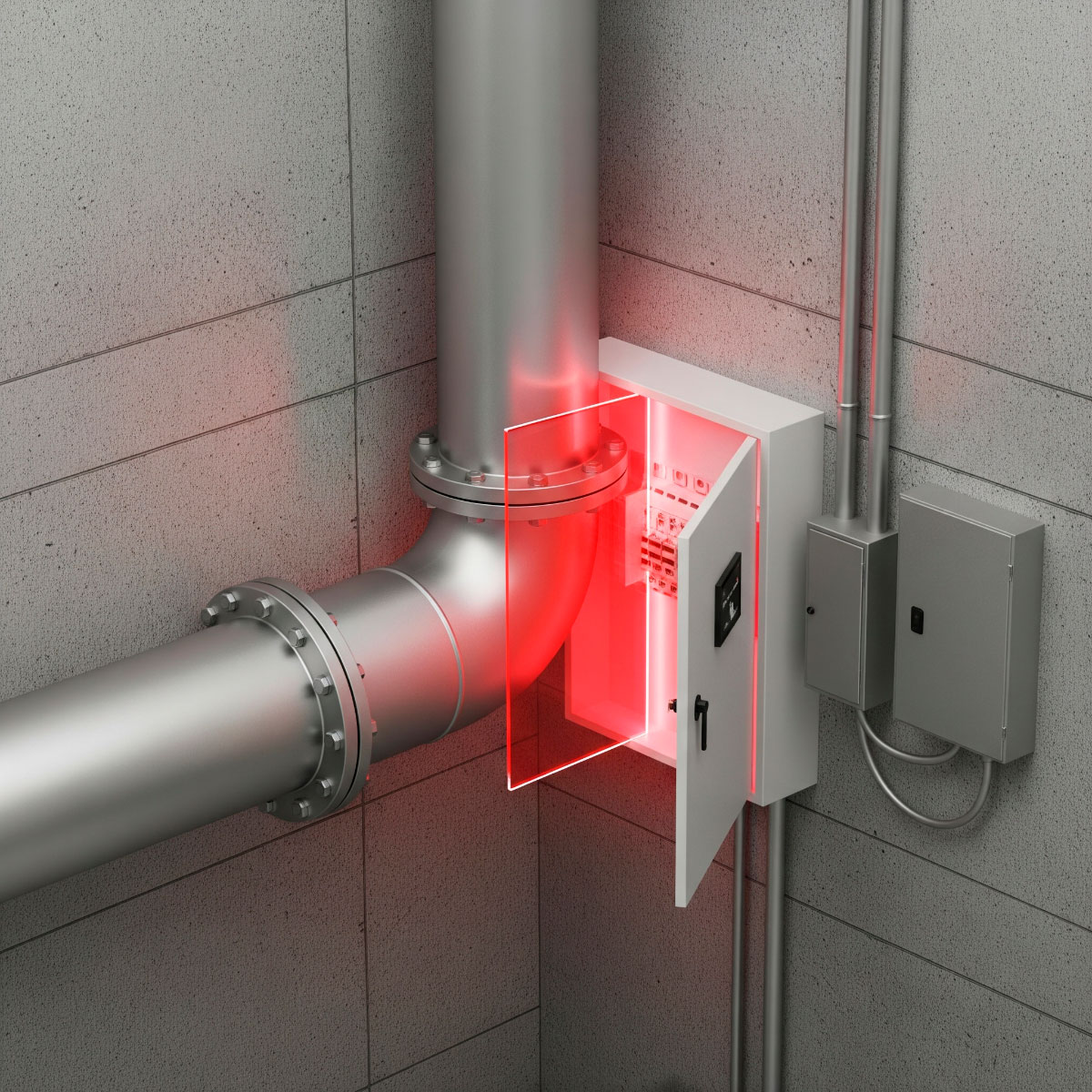

Functional interferences: the millimetre problem

Less obvious but equally critical are functional interferences. These occur when nearby elements do not collide, but their proximity compromises their operability or maintenance. A typical case is a pipe installed just a few centimetres away from an electrical panel. The solution is to define separation zones around sensitive equipment, something that tools such as Navisworks or Revit can automate by means of proximity rules.

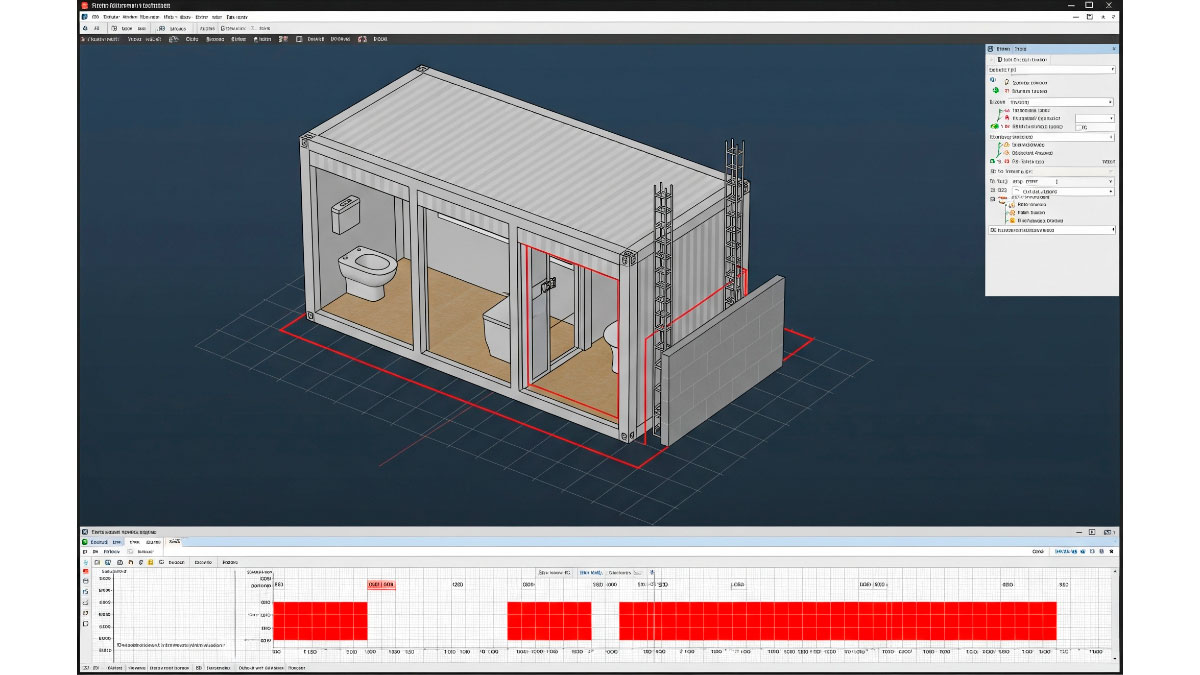

Temporal interference: when planning fails

4D conflict introduces an even more critical variable: time. In these cases, the error is not spatial, but sequential. For example, scheduling the installation of a transformer before closing the building’s façade may force the dismantling of structures already in place. Platforms such as Synchro Pro integrate schedule simulations with the BIM model, so that inconsistencies are alerted before they materialise on site. According to a McGraw Hill Construction report, projects with 4D management reduce delays due to poorly planned logistics by up to 20%.

By Raúl Soriano, Senior Modeller in the Architecture Department at Amusement Logic