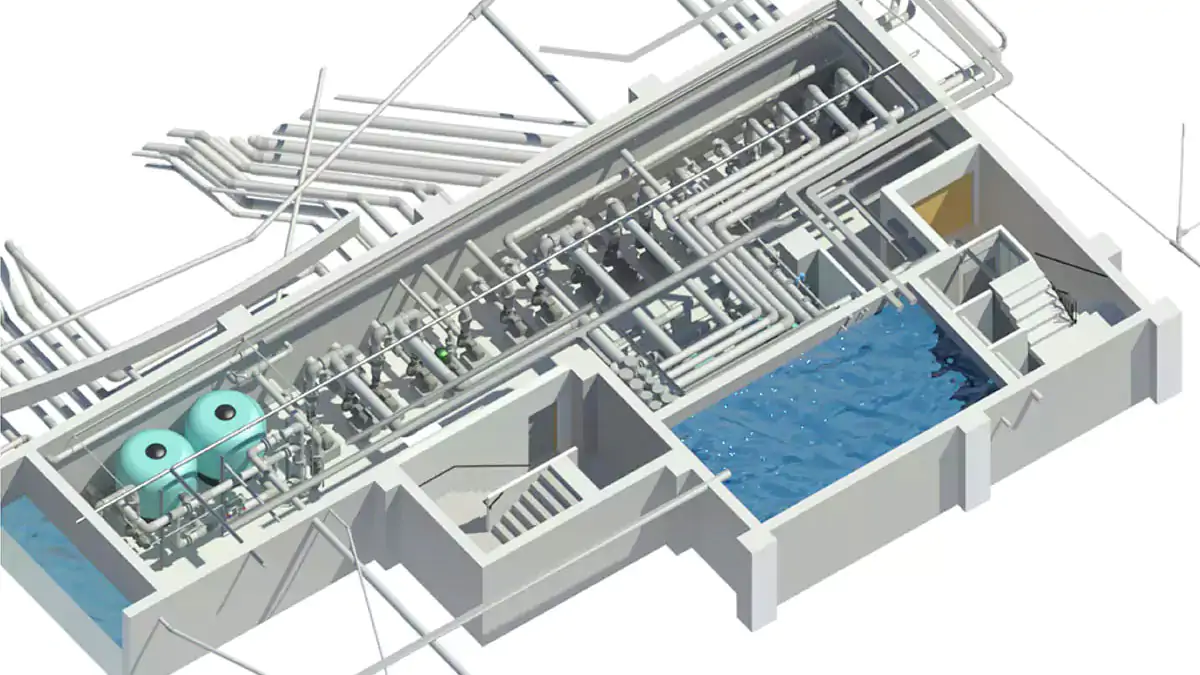

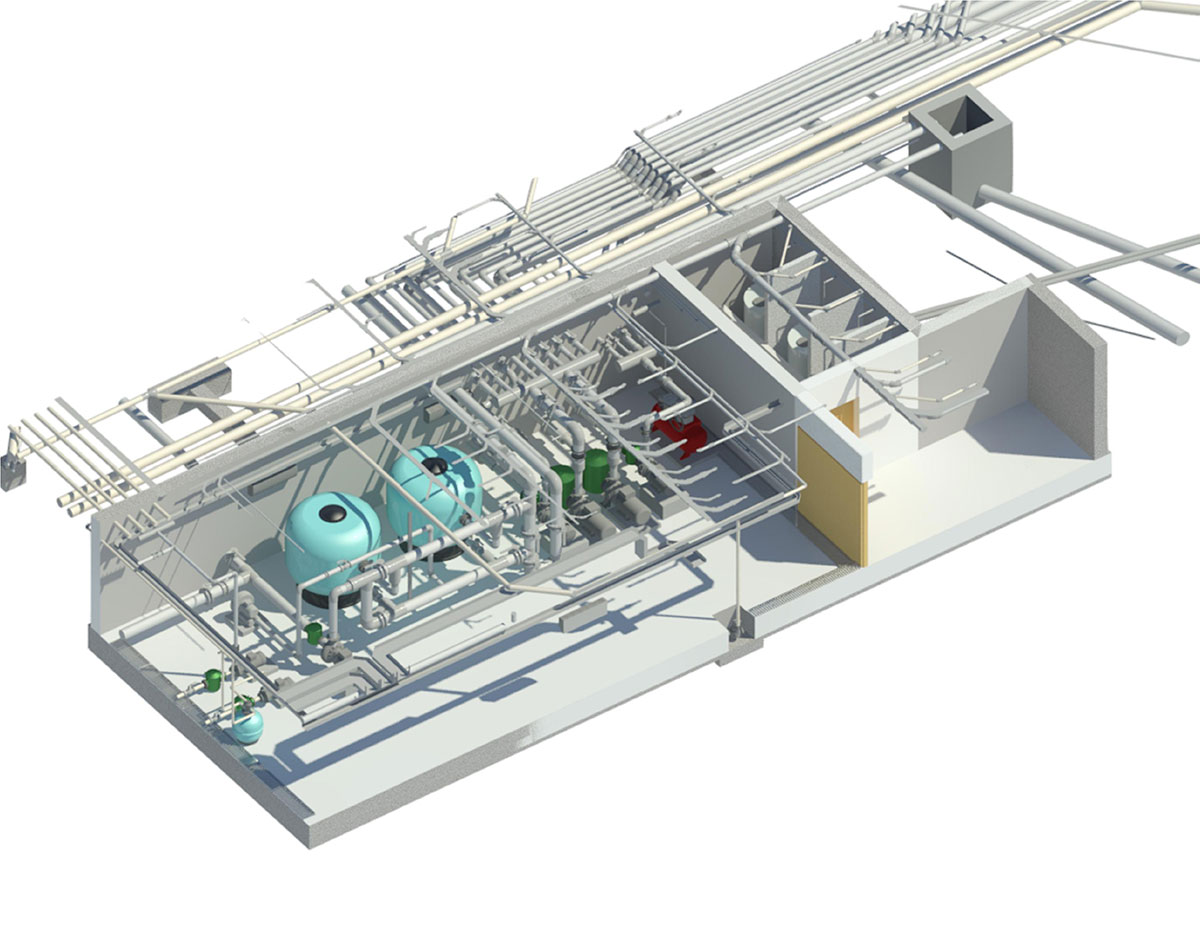

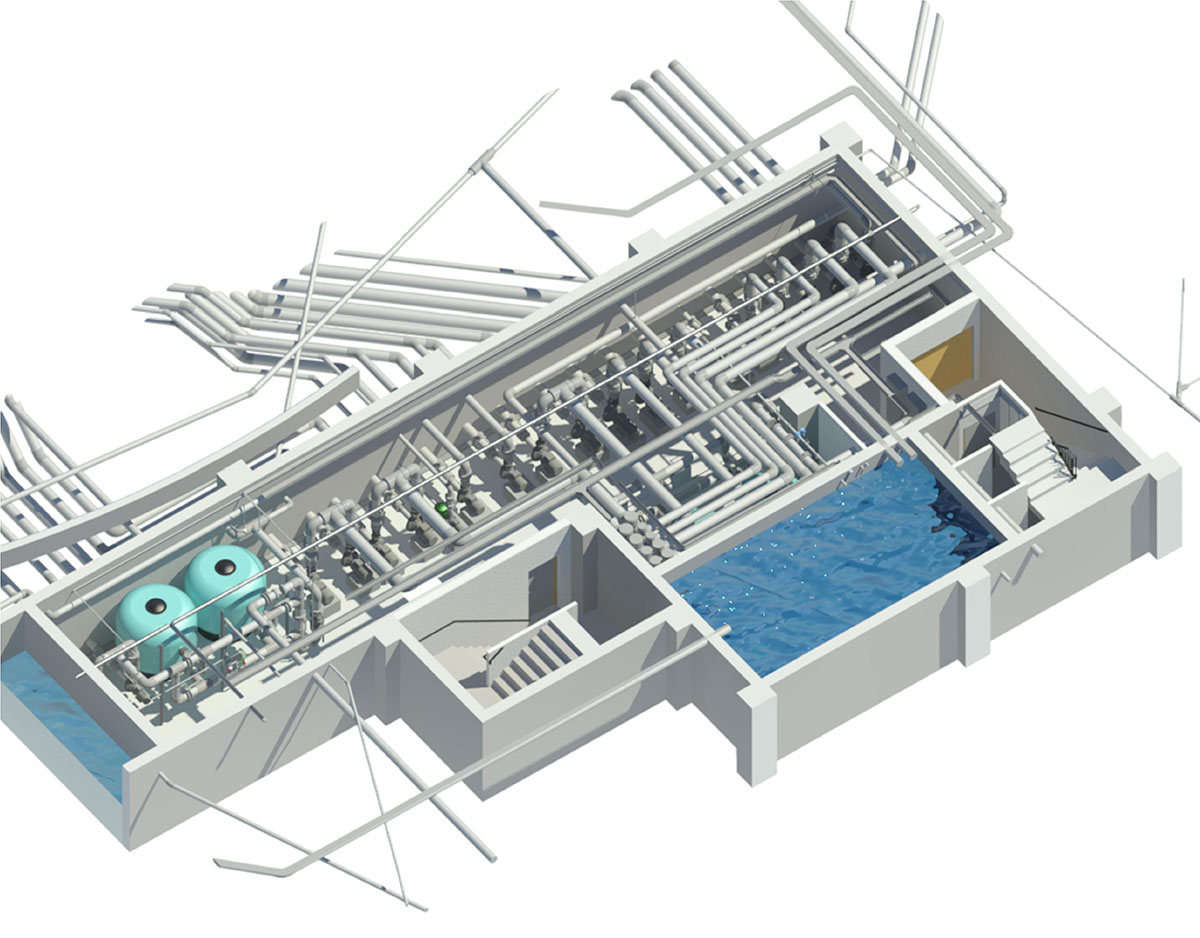

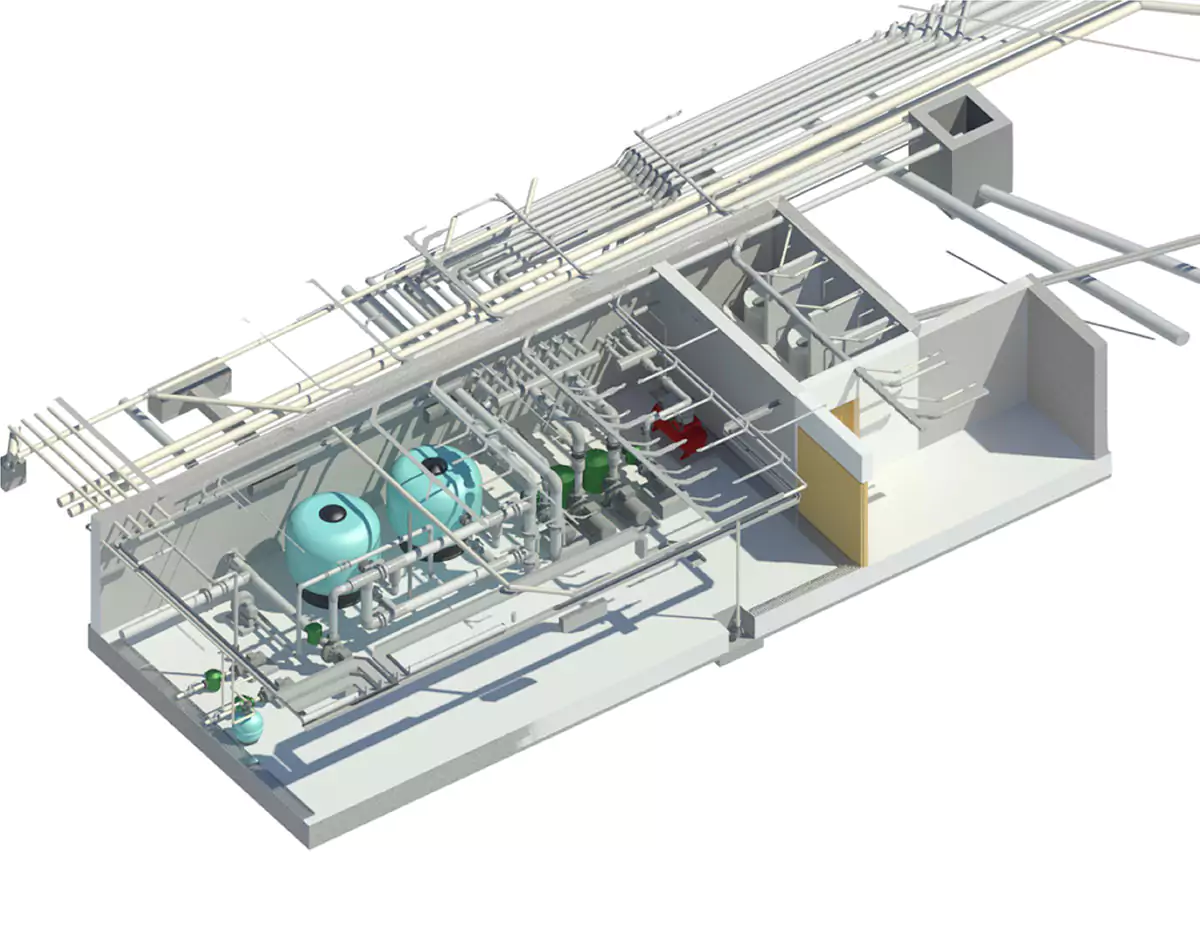

Hydraulic pumps work behind the scenes in water parks and attractions, and are responsible for the water running down the slides, cascading down the waterfalls, or gushing out as if by magic from the games, arches and figures that the children enjoy. In conventional installations, the pumps work continuously and drive the maximum flow for which they are manufactured. In this sense they’re a rigid element with two options: on or off. However, in the installations we develop, we always encourage the incorporation of a device that turns the hydraulic pump system of any attraction into a much more efficient, flexible and durable installation. We’re referring to speed variators

The pumps’ power is precisely calculated so that they provide the specific hydraulic flow rate for the operation of the different water attractions in any project. However, flow rate requirements vary in complex hydraulic networks, whether due to operating point adjustments, low user traffic or many other factors. In traditional rigid systems, flow is regulated mechanically by the manual action of throttle valves. This system generates a fictional load loss while the pump, i.e. its motor, is running at full power. In this case, what we do is reduce the pump’s performance without reducing either the power or the electrical consumption of its motor.

On the other hand, a speed variator is an electronic instrument with which we modify the frequency of the electrical current feeding the motor and with it, its rotation speed. Consequently, the flow it provides to the attraction is proportionally modified. To summarise, with the variators we correct the pump’s flow whilst we adjust the motor’s power and electrical consumption that makes it work, without the need to resort to the mechanical system of valves.

There are many advantages to using variators in water parks and other attractions:

-They facilitate the automation of hydraulic systems, remote control and operation monitoring.

-They minimise wear and tear on components and increase the life of motors and pumps, since the progressive on/off feature eliminates the mechanical and electrical stress on them.

-They increase the useful life of the hydraulic network by avoiding overpressure at startup and shock due to the fall of the water column on stopping.

-As a consequence of the two previous benefits, the variators reduce maintenance needs.

-They improve the safety of the attractions by maintaining constant operating parameters such as power, flow rate, etc.

-They protect the installation against voltage drops or power cuts, as they allow the progressive stopping and control of the kinetic energy.

-They save energy by adapting the electricity consumption to the demand of each moment.

As a result of all the above, the use of variators has an impact on the profitability of hydraulic installations. At the same time, by reducing electricity and/or fossil fuel consumption, their implementation results in the reduction of greenhouse gas emissions and therefore benefits the planet.