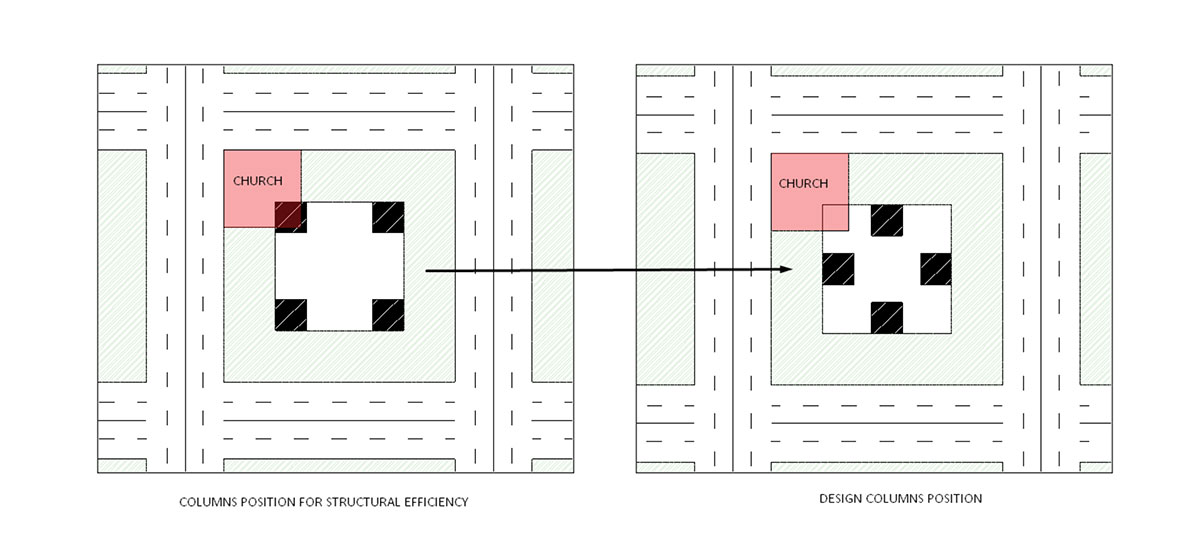

The Citigroup Center stands at 601 Lexington Avenue in New York City as a landmark skyscraper. But, beyond its design, its structural design and construction, is an intriguing story. One of the peculiarities of its structural design is precisely the location of its columns. The columns are located in the centre of each of the four sides, rather than at the corners, as is customary. With this design, the architects fulfilled Citigroup’s promise to the church to which part of the land belonged: to build a new church on the same corner, independent of the new building and without columns crossing it.

However, William LeMessurier, the engineer responsible for the Citigroup Center structure, received a call from an engineering student. She warned him of the building’s vulnerability to wind forces, which, under certain unconsidered assumptions, would increase the stresses in the building’s joints by 150%. Although he was confident that his welded joint design could withstand this increase, LeMessurier discovered that the construction company had opted for bolted joints, which were quicker and cheaper. Upon recalculation, the engineer realised that the building would collapse if hit by a storm of an intensity that, according to records, recurs approximately every 60 years.

To solve the problem, teams of welders welded all the bolts in the existing joints at night, after the regular working hours of the skyscraper’s employees. In addition, an emergency plan was put in place to evacuate a 10-block radius around the building while repairs were carried out. This incident represents an outstanding example in the history of construction of how engineering challenges must be addressed.

By Alberto Lopez, Senior Structural Engineer in Amusement Logic’s Architectural Dept.

https://www.flickr.com/photos/schizoform/25910655104