The basic recommendations for water saving in the domestic sphere cannot be applied for projects with higher water requirements, such as water parks. For these types of leisure and tourism facilities, solutions supported by adapted engineering development must be implemented. Amusement Logic regularly carries out this type of engineering development in the design and construction of water parks.

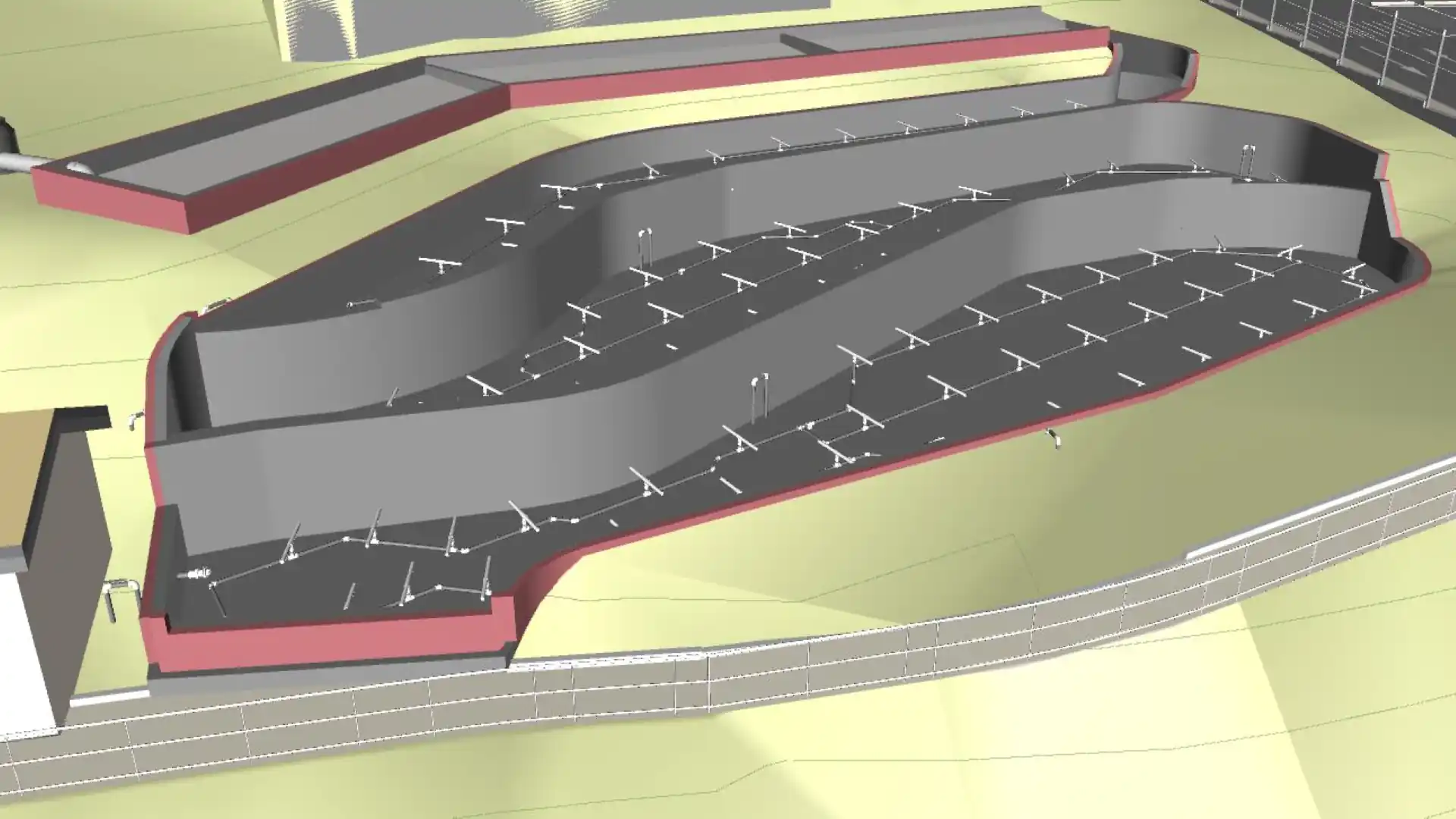

In one of our most recent projects, we implemented the design of a decantation and dechlorination basin using forced aeration. In this way, we provided the water park with a system for the reuse of water from filter washing. This water can now be used to irrigate the green areas of the water park. In addition, the decantation and dechlorination system avoids overloading the sewage network with the flows from the filter washing.

The pool has a total volume of 360 m3, of which 273 m3 correspond to the net catchment volume, the period of which is approximately 13 days. These factors make it possible to use a daily flow of water from the pool of approximately 21 m3. As the average irrigation demand in this particular water park is 37 m3/day, the water treatment system and the designed pool supplies 57% of this daily demand, which is a great saving.

With this type of solutions, Amusement Logic provides its water park projects with a system for recycling and efficient use of water. At the same time, thanks to its careful design, it becomes part of the landscape environment of the water park.

By Francisco Lozano, MEP engineer in Amusement Logic’s Architecture Department.