The filter cleaning operation of the pool purification system of a water park, whether it is part of a hotel or resort, a campsite, a shopping centre or an attraction in itself, is carried out 2 or 3 times a week as part of the maintenance work. The water used for this, instead of being disposed of down the drains, can be reused for watering the landscaped areas. However, this water must first be treated to ensure that it is suitable for this purpose.

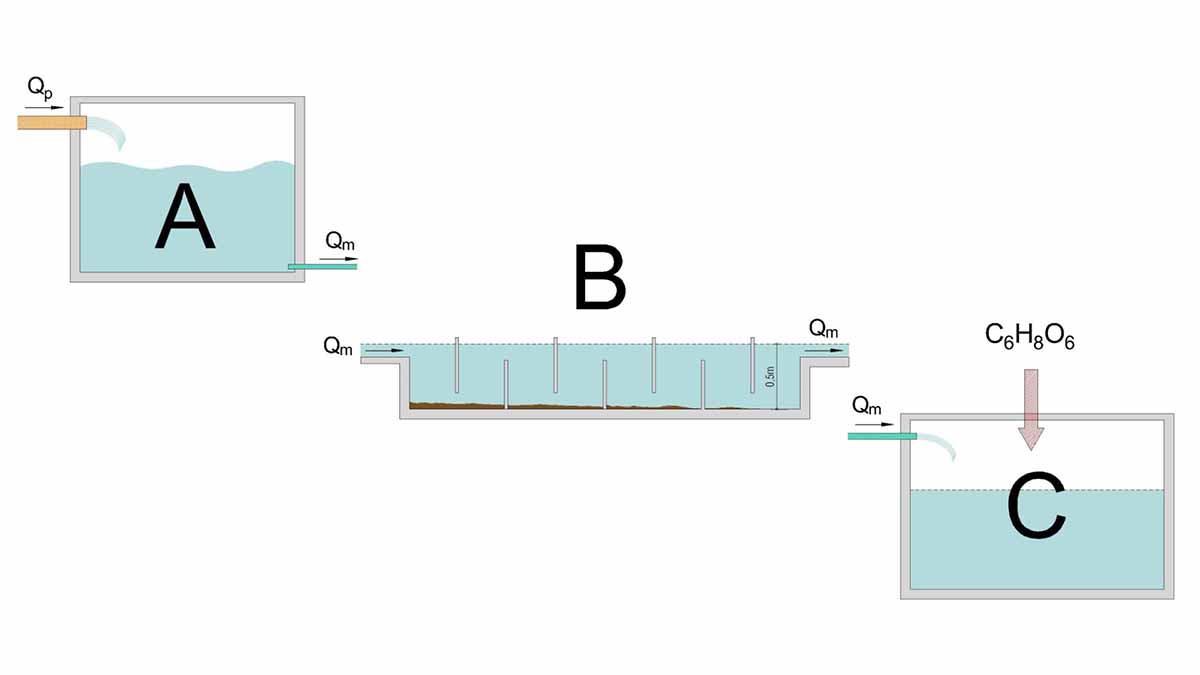

The treatment that makes this water a reusable resource is carried out in three distinct phases, as shown in the following graph:

In order of application, these are the phases:

-Phase A: lamination of the filter washing flows (Qp), so that their peaks are reduced by around 70%. This operation is carried out in the lamination tank, the dimensions of which are calculated according to the particular parameters of each project. In addition to reducing flow peaks, the tank also performs the function of pressure relief.

In this table, the ordinate axis corresponds to the flow rate in m³/h (Q), while the abscissa axis reflects the time in minutes. Therefore, in orange we see the pattern of the flow peaks due to filter washing (Qp). In red, on the other hand, the laminar flow rates (Qm) are represented.

-Phase B: settling of the laminated flow rate (Qm); the suspended solids carried away by the water from the filter washing are deposited. The proposed decanter is rectangular and has 8 chambers. Its dimensions are defined according to the input flows and the specific demands of each project.

-Phase C: elimination of chlorine. The geometry and location of this tank in the aquatic park is determined according to the space available (outside or inside, above ground or partially buried). This configuration will determine the most appropriate dechlorination treatments. In the example, the neutralisation of chlorine by the addition of vitamin C is considered. Once the corresponding chemical reactions have taken place, the water, treated and useful for irrigation, is sent to the irrigation tank.

With this treatment, the water from filter washing, which is often sent to the sewage system, is recycled and used for other purposes, such as irrigation. Amusement Logic’s engineers develop this type of water treatment and dechlorination systems in the water parks of hotels and resorts, campsites, shopping centres or leisure and tourism complexes.

If you are interested, you can read what we said about dechlorination with vitamin C here: Water dechlorination with vitamin C.

By Luis Llor, senior hydraulic engineer in the Architectural Department of Amusement Logic