Water has a high volumetric modulus of elasticity and is therefore considered incompressible. However, an undesirable and harmful phenomenon, closely related to the compressibility of water, sometimes occurs in the pipe networks of water parks. This is water hammer.

Water hammer occurs in the pipes of a water park when there are strong overpressures due to sudden variations in flow. As a result of this phenomenon, the pipes suffer detrimental effects, ranging from degradation of the materials to bursting.

The particular situations in which it is advisable to take into account this compressibility, since they can produce the water hammer phenomenon, are as follows:

-When a network transits, in a short period of time, from supporting a considerable flow to zero flow. For example, this transition occurs when a shut-off or flow control valve is operated, or when a pump is stopped.

-When, conversely to the previous situation, the network goes from a zero flow to a significant flow. In this case, it would occur with the start of a pump.

But let us analyse the phenomenon from a qualitative point of view:

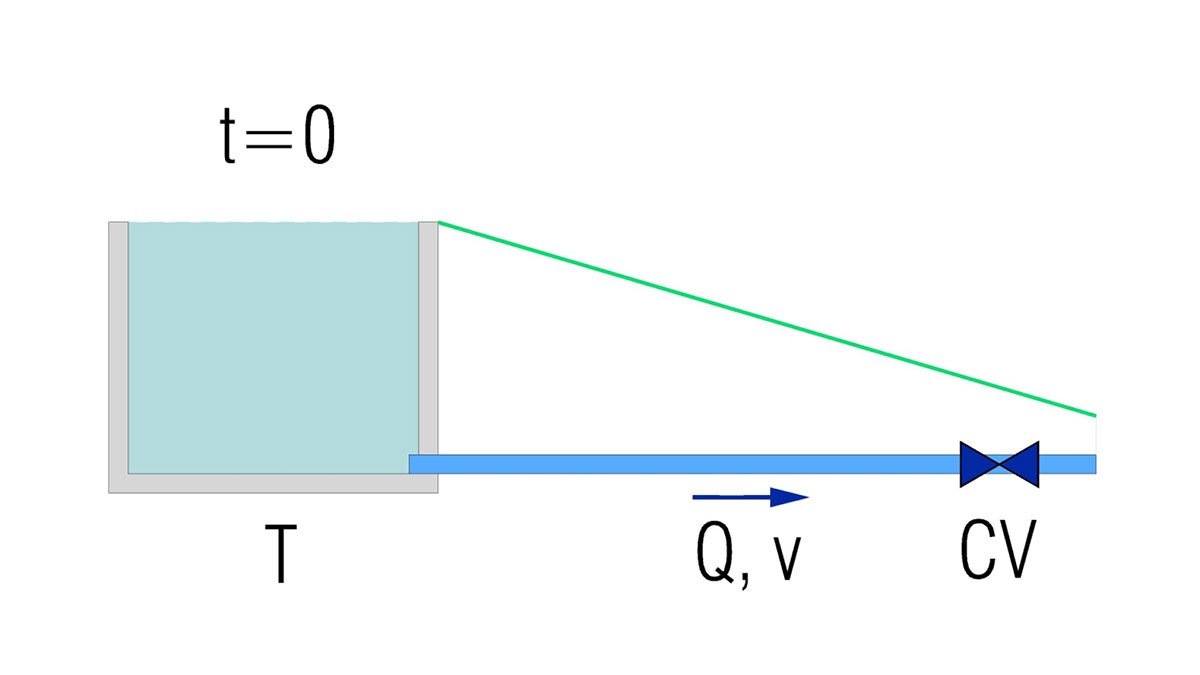

From a tank (T) starts a conduit that has a shut-off valve (CV) at the downstream end. Both the water and the pipe are susceptible to deformation when faced with a pressure variation.

Initially (instant t=0) the shut-off valve is open, so a flow (Q) flows through the pipe at a given velocity (v).

The green line represents the load line of the pipe, when the tank is draining.

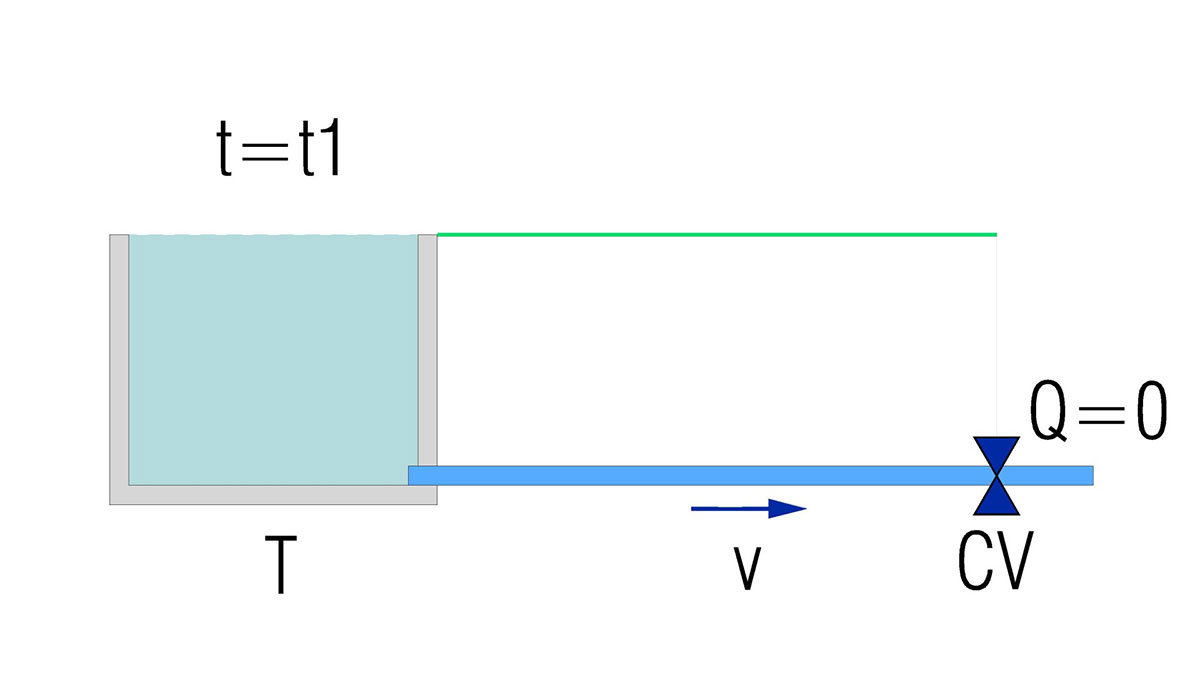

Now, at a specific instant (t=t1) the shut-off valve closes instantaneously, which interrupts the outflow.

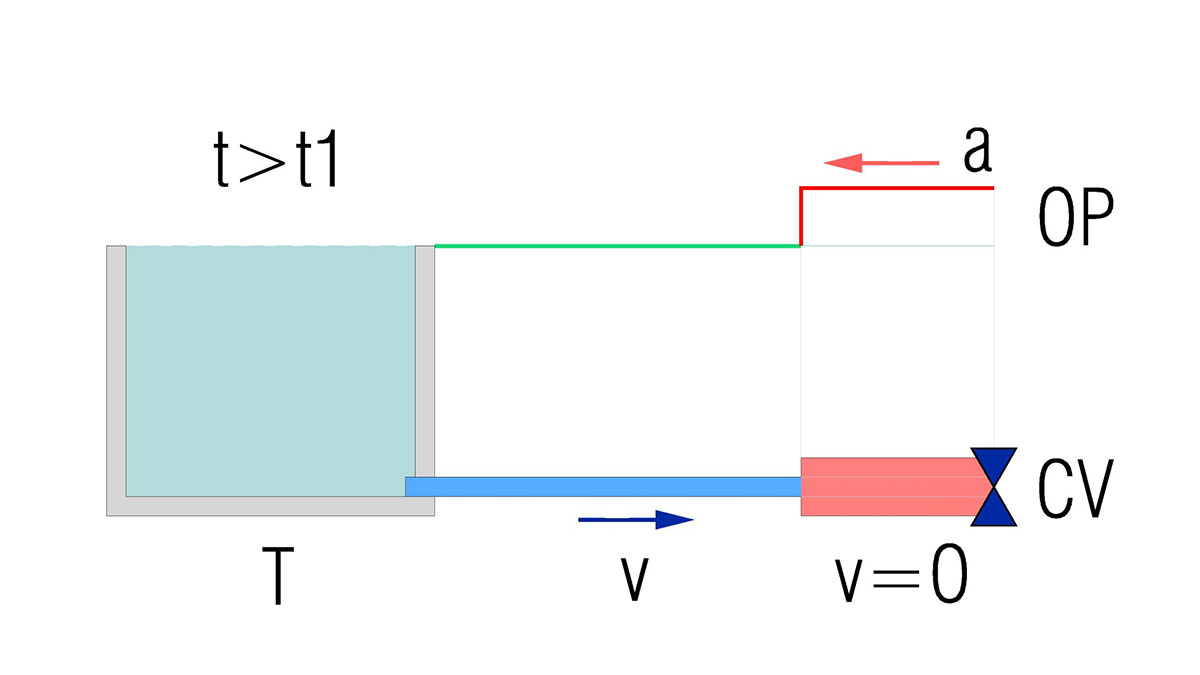

From this moment (t>t1), the kinetic energy of the fluid begins to be transformed into potential energy, which in turn causes an overpressure (OP) that compresses the water and expands the pipe. The overpressure wave propagates from the closed valve upstream, with a velocity (a), and deforms the pipe (the section of pipe deformed by the compressed water is shown in red).

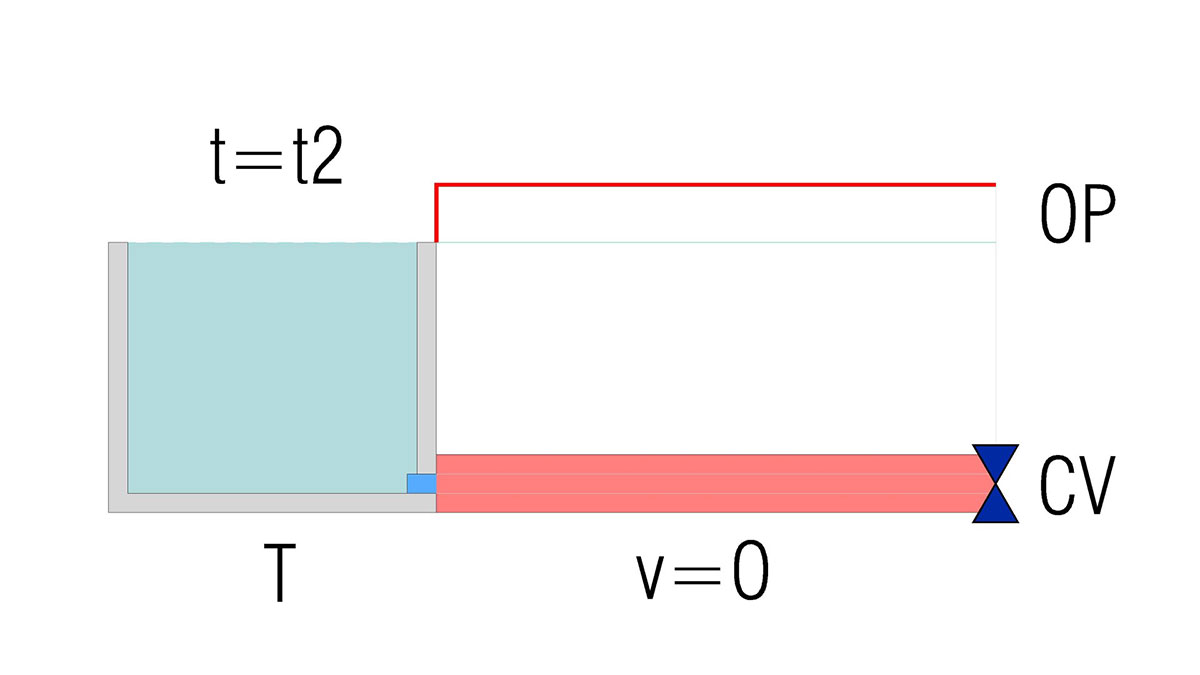

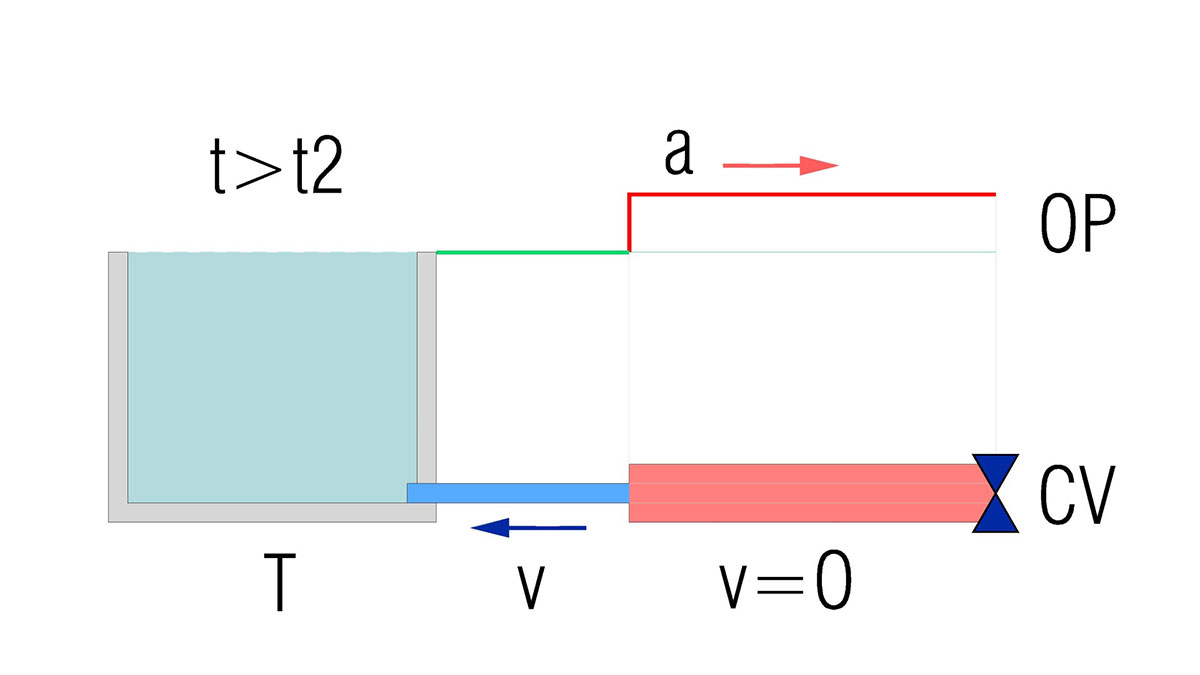

When the pressure wave reaches the tank, the entire pipe is under overpressure. At that instant (t=t2) a reflection of the wave is produced, that is to say, the pressure wave begins to advance downstream.

From that instant (t>t2), the reflected wave propagates downstream, the water recedes towards the tank and the pipe contracts and recovers its initial position.

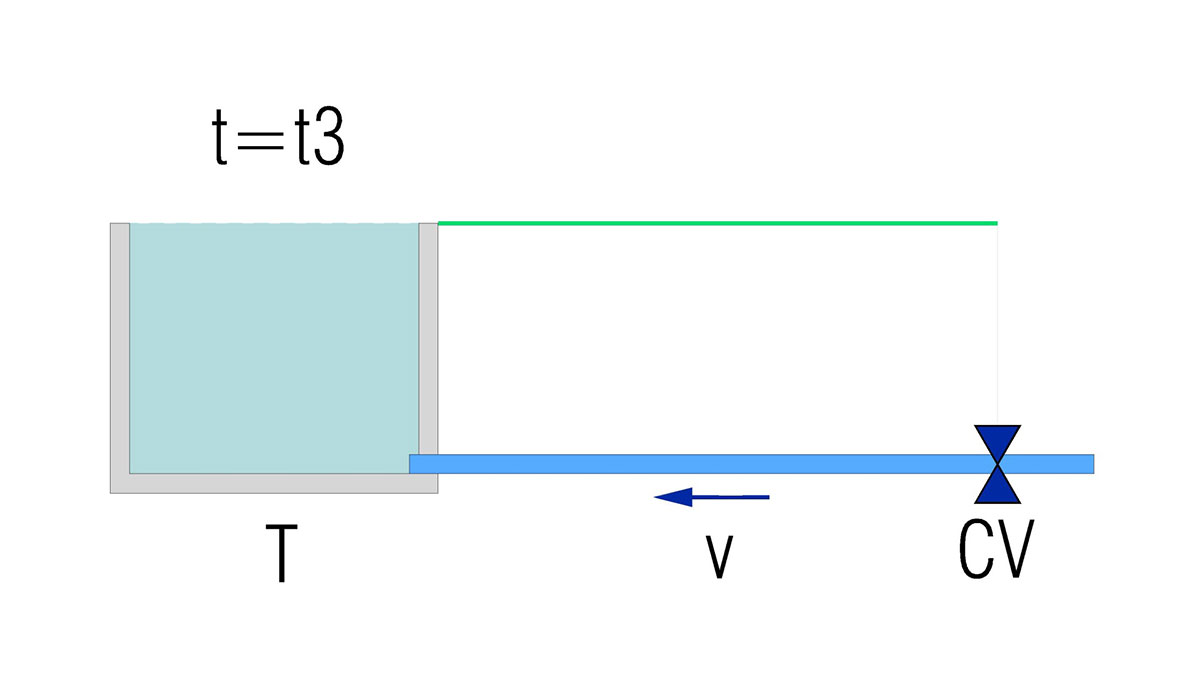

When the pressure wave reaches the shut-off valve (t=t3), all the water in the pipe is circulating towards the tank, and the entire pipe has compressed and recovered its original size.

The phenomenon described above is called the direct phase of the water hammer. From this moment on, the previous process is repeated, but in reverse. This is the reverse phase of the water hammer. In this phase, the circulation of the water occurs in the opposite direction; a negative pressure wave front is generated and the dilation of the water instead of its compression; the pipe contracts instead of expanding. These direct and inverse phases follow each other cyclically, until the mass of water inside the water park’s hydraulic network pipe reaches equilibrium.

The cyclical and violent variation of pressures in the pipe is a very harmful effect, which ends up deteriorating the pipes and their fittings. We will leave for a future issue the quantitative aspects of water hammer, the determination of the type of hydraulic infrastructures of the water parks in which the phenomenon is triggered and the necessary measures to avoid or mitigate it.

By Luis Llor, senior hydraulic engineer in Amusement Logic’s Architecture Department.