Beyond the design and construction of efficient leisure and tourism facilities, an aspect that Amusement Logic always emphasises, the environmental commitment in their development, also involves waste management. For this reason, contractors must prepare a Waste Management Plan adapted to the regulations in force in order to carry out these projects.

One of the fundamental aspects of waste management is the recycling of metals. In this respect, more metal is recycled worldwide than paper, glass and plastic combined. In fact, in general, all metals sent to landfills are reused. From an environmental point of view, metal recycling reduces water and air pollution, as well as the volume of mining waste, by up to 70%. Specifically, recycling one tonne of steel saves 1,400 kg of iron, 740 kg of coal and 120 kg of limestone. And new products made from this metal contain around 37% recycled steel.

Environmental certifications take these processes into account and strategies and protocols have been established for their implementation, so that buildings that implement them get a better rating. For example, the LEED 4.1 standard (based on a maximum 100-point rating), allocates 13 points of its index to materials and resource issues, 10 points judged on sustainability criteria and 33 points for energy criteria. So, to obtain the highest ratings (Gold, 60 to 79 points, or Platinum, more than 80 points), it is essential to consider recycling in construction.

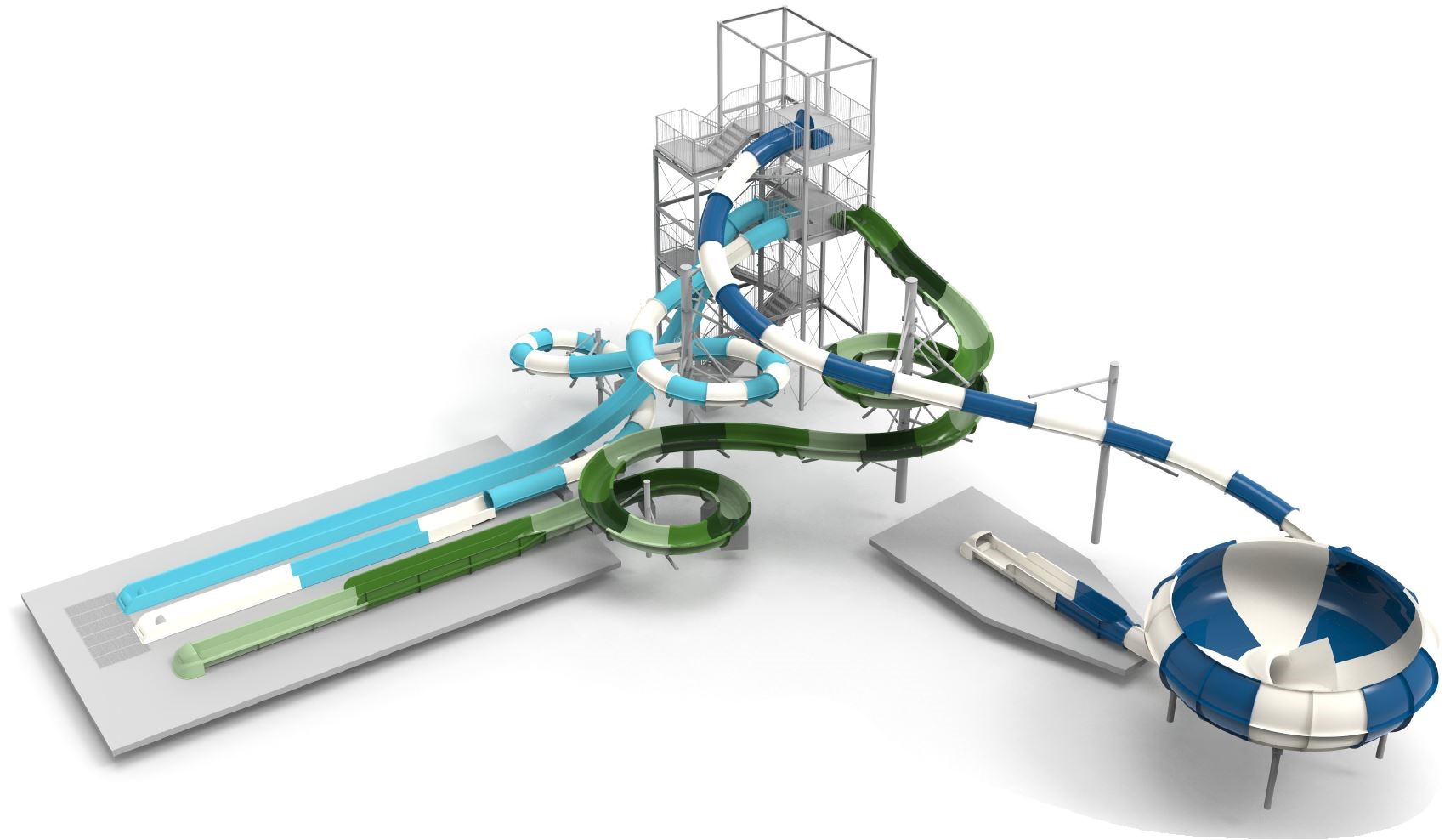

In the case of Amusement Logic’s leisure and tourism projects, one of the most important applications of recycled steel is precisely in the construction of structures, such as the slide exit towers.

By Raúl Soriano], senior structural modeller in Amusement Logic’s Architecture Department.