‘Duplex protection’ is based on the simultaneous application of two classic corrosion protection systems to steel: galvanising and lacquering. This solution is commonly used when the use of stainless steel would be economically unfeasible, and is common in metal structures exposed to particularly aggressive environments, such as industrial settings, coastal areas or in contact with water containing chemical agents. Depending on the specific configuration, the duplex system increases the durability and effectiveness of the protection by between 1.2 and 2.5 times compared to the application of each method separately.

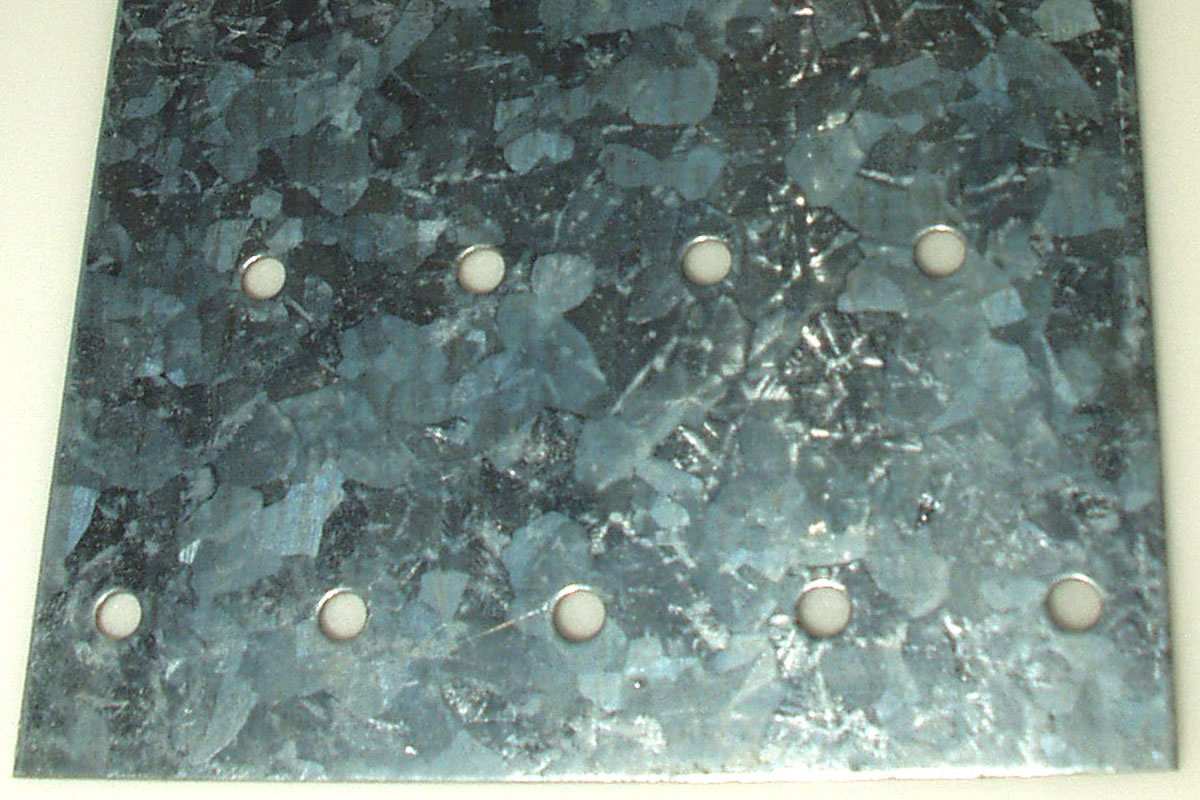

The process begins with galvanising, which creates a layer of zinc on the steel. As zinc is a more reactive metal than iron, it acts as a sacrificial anode. In the presence of oxygen, zinc reacts first to form zinc oxide, which in turn reacts with atmospheric carbon dioxide to generate a stable layer of zinc carbonate. This dark grey, highly resistant compound forms an effective barrier that protects the underlying steel even from minor surface damage such as scratches or pitting.

The required thickness of the galvanised coating is determined based on the thickness of the metal to be protected, the environmental exposure category — normally defined by the ISO 9223 standard — and the standard applicable to galvanising, such as ISO 1461 or ASTM A123. This thickness usually ranges from 55 to 200 micrometres.

A surface finish coat is then applied. This can be a powder coating — in accordance with ASTM D6386 and often without the need for a primer — or a polyurethane or epoxy paint, in accordance with standards such as ISO 12944-5. In addition to acting as an additional physical barrier against moisture and corrosive agents, this coat provides colour. The typical thickness of this finish is between 90 and 300 micrometres.

Overall, the duplex system offers a total protective thickness ranging from 150 to over 400 micrometres. To guarantee its quality and durability, rigorous control is essential, including accurate thickness measurement using methods such as magnetic induction or phase-sensitive Eddy currents. In addition to these measurements, performance tests, such as salt spray testing and adhesion testing, are also carried out.

By Miquel Solís, senior architect in the Architecture Department at Amusement Logic