The evolution in the manufacture of water slides directly reflects the discovery of new materials and their consequences in structural engineering. Let’s see how:

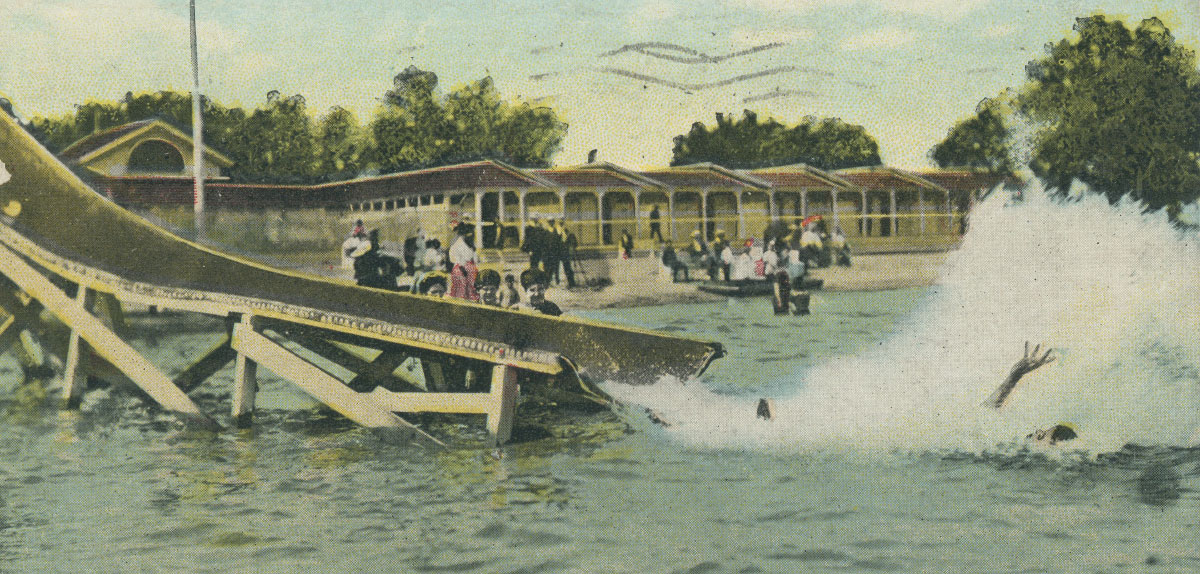

In the early 20th century, water slides were mainly made of wood and metals such as steel or aluminium. These materials offered adequate mechanical strength but had considerable drawbacks, such as corrosion problems, high surface friction, low user-comfort and high maintenance requirements.

Later, between the 1950s and 1970s, treated metals were incorporated, improving the durability of water slides, although limitations related to thermal behaviour and geometric and design possibilities persisted.

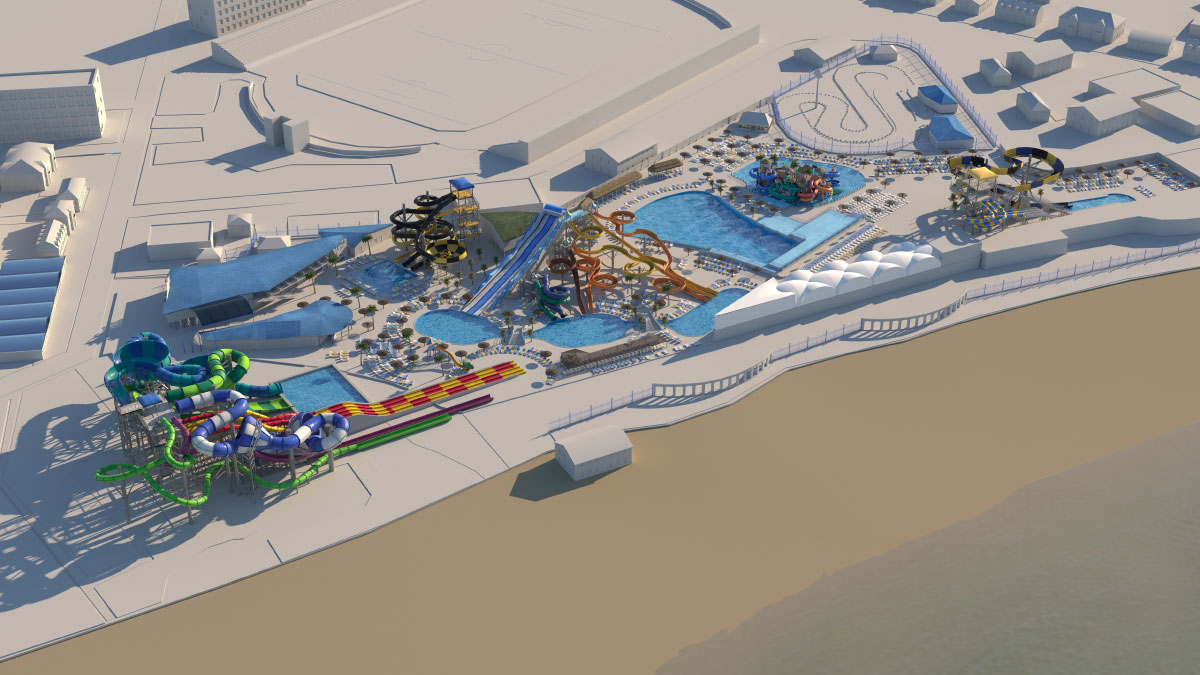

A significant change occurred in the 1970s with the introduction of composite materials, specifically fibreglass reinforced polymer resins. This technological leap provided a better strength-to-weight ratio, greater durability against environmental agents and, above all, unprecedented design freedom. Curved and complex shapes finally became possible.

Since the 1990s, the continuous optimisation of these composite materials has been complemented by the widespread use of computer simulations in design and structural analysis. All of this has made it possible to further increase the safety, efficiency and sustainability of modern water slides.

By Carlos Rodríguez, specialist in Hydraulics and Water Attractions in the Architecture Department at Amusement Logic.